Industrial Crystallizers Selection & Scale-Up Guide

Industrial crystallizers sit at the heart of modern chemical processing. They are the systems that transform solutions into high-purity solids for industries as varied as battery-grade lithium, fertilizers, and industrial chemicals. The stakes are high: product quality, yield, and overall process economics often depend on how well the crystallization plant is designed and controlled.

Whiting Equipment Canada Inc., backed by over 140 years of engineering expertise, delivers crystallization and evaporation systems for these demanding applications through its licensee, Swanson Technology Inc. Swenson has been involved in lithium purification since the 1950s and brings decades of experience in crystallization system design, scale-up, and operation. Together, Whiting and Swenson focus on solutions that are “Built to Perform. Designed to Last. Trusted Worldwide.”

Crystallization fundamentals

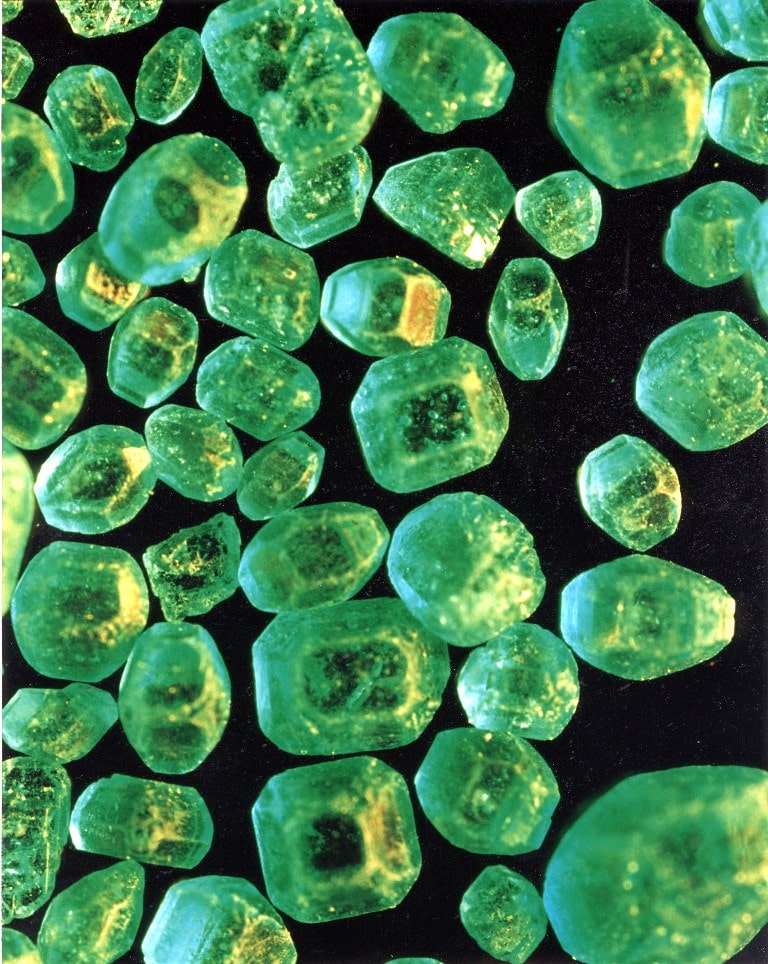

Crystallization separates and purifies solids from a solution. By carefully managing crystal formation and growth, producers can control crystal size, shape, and purity—key properties that determine product performance and downstream handling.

This control is particularly crucial in the rapidly growing lithium sector. Lithium must be refined from brines or hard rock minerals, with contaminants removed to achieve the battery-grade purity required for use in batteries. Swenson’s experience spans lithium hydroxide monohydrate (LiOH·H₂O), lithium carbonate (Li₂CO₃), lithium chloride (LiCl), and lithium sulphate (Li₂SO₄). Their work shows how crystallization can consistently deliver high-purity products by controlling nucleation and growth.

Every successful crystallization project begins with a solid understanding of thermodynamics and chemical behavior. This foundation enables the design of efficient, economical, and effective processes for removing contaminants—whether in the application of lithium, other critical minerals, fertilizers, industrial chemicals, or other demanding sectors.

Supersaturation control levers

Supersaturation is the driver of crystallization. It occurs when a solution contains more solute than it can hold at equilibrium, creating conditions for crystals to form. Managing supersaturation is therefore crucial in controlling nucleation, growth, and ultimately, the purity and size of the product crystals.

Swenson uses three main approaches to create supersaturation:

- Evaporative crystallizers remove solvent through evaporation to raise solute concentration. They are most effective when solubility increases with temperature.

- Cooling crystallizers lower the solution temperature through cooling, thereby reducing solubility and promoting crystal formation. Controlled cooling rates influence the final crystal size distribution, thereby affecting impurity removal efficiency.

- Reactive crystallizers use a reaction between two components to produce a crystalline material. This type of operation can often be performed more profitably in a crystallizer than in a separate reactor. An example of reactive crystallization is the production of ammonium sulphate from ammonia and concentrated sulfuric acid.

Swenson’s modeling and pilot testing refine these methods, helping clients keep supersaturation in the optimal zone. This balance enables crystal growth without uncontrolled precipitation, thereby minimizing fouling and maximizing the recovery of high-purity lithium and other valuable products.

Residence time & agitation

The time crystals spend in a crystallizer and the manner in which they are kept in motion both affect their final characteristics.

- Residence time must be long enough for crystals to grow, but not so long that they degrade or produce excessive fines. Swenson’s Draft Tube Baffle (DTB) and Forced Circulation (FC) crystallizers, tested at pilot scale, are designed with these considerations in mind.

- Circulation maintains even supersaturation, prevents crystals from sticking together, and keeps them suspended in the solution. Proper mixing promotes uniform growth, while excessive agitation risks breaking crystals into fine particles.

Swenson’s pilot testing provides data on fouling, scaling, and crystal growth under real-world conditions, giving our engineers the information needed to optimize residence time and circulation for commercial-scale plants.

Crystallizer types (DTB, FC, BVC, SCC)

The type of crystallizer chosen is crucial to the entire process. Swenson’s pilot facilities can test multiple designs, generating the data needed for commercial plant scale-up.

- The Draft Tube Baffle (DTB) produces narrow crystal size distributions by dissolving smaller crystals, thereby allowing larger, existing crystals to grow further.

- Forced Circulation (FC) is the best choice for feeds that require high evaporation rates, contain scaling compounds, achieve crystallization in inverted solubility solutions, or have relatively high viscosity.

- Batch Vacuum Crystallizers (BVCs) are used for special cases that require very low operating temperatures, achievable only with very high vacuum. These applications involve relatively small amounts of material, or when the material being processed must be handled on a less-than-continuous basis.

- Surface Cooled Crystallizers (SCC) are employed for operation at temperatures below which it is not economically feasible to use vacuum equipment, or for solutions with very high boiling temperatures.

Crystal size distribution control

Crystal size distribution (CSD) affects material handling processes, including centrifuge performance and washing efficiency. Larger, uniform crystals are easier to wash and dewater, while fines can reduce purity and complicate downstream processing.

Swenson focuses on CSD from the earliest stages. Bench testing provides crystal data on yield, purity, and morphology, while pilot testing extends this to washing requirements and centrifuge performance. By adjusting supersaturation, residence time, and agitation, Swenson engineers tailor CSD to meet the specific demands of each product, whether it is lithium or other critical minerals, salts, industrial chemicals, or fertilizers.

Anti-scaling strategies

Scaling reduces heat transfer efficiency and restricts flow, resulting in downtime and increased costs. Swenson’s pilot testing identifies fouling and scaling tendencies before full-scale construction, allowing for targeted design strategies.

Mother liquor recovery

Mother liquor, the liquid left after crystals are separated, contains both impurities and valuable residual product. Efficient recovery is crucial for yield, purity, and economic viability.

Swenson’s lithium crystallizers are designed to maximize recovery of high-purity product, which inherently means effective handling of mother liquor. Pilot testing provides centrifuge performance data, ensuring solids are well separated from the liquid. Depending on the process, mother liquor may be recycled, further processed, or treated for disposal, always with the goal of minimizing losses and enhancing process efficiency.

Scale-up pitfalls

Moving from lab to commercial scale brings risks. Swenson addresses these with a staged approach:

- Modeling and simulation to understand thermodynamics and impurity behavior.

- Bench testing in glassware to confirm feasibility and gather physical and crystal data.

- Pilot testing in DTB, FC, evaporative, and cooling crystallizers to simulate real conditions, including fouling and centrifuge performance.

- Process design and equipment sizing based upon test data and experience.

- Fabrication, delivery, and commissioning to bring the system online.

This structured process reduces risks such as unexpected CSD shifts, fouling, inefficient impurity rejection, or unstable operation.

Case applications by industry

Industrial crystallizers serve multiple sectors, and Swenson’s work spans the lithium and other critical minerals, chemical, and fertilizer industries.

- Lithium & battery raw materials: Demand for lithium has surged with the growth of electric vehicles and energy storage. Crystallization is a core refining step, applied to compounds such as LiOH·H₂O, Li₂CO₃, LiCl, and Li₂SO₄. Systems are designed to maximize recovery, remove contaminants, and achieve battery-grade purity.

- Industrial chemicals: Crystallizers, evaporators, and dryers support consistent production of commodity and specialty chemicals. Precise control over supersaturation and CSD ensures quality and process reliability.

- Fertilizers: Potash, ammonium sulphate, and nitrates are often produced as crystals. Tailored crystallization enhances purity, flow, and dissolution rates, while minimizing dusting or caking.

Conclusion

Industrial crystallizers are crucial for separating and purifying desired compounds from contaminants in solutions to produce high-purity solids across key global industries. With expertise built over decades and reinforced by pilot facilities, Whiting and Swenson provide systems that manage crystallization fundamentals, control CSD, reduce scaling, and recover mother liquor efficiently. By following a structured scale-up path, they reduce risk and deliver crystallizers that meet the specific demands of lithium, critical minerals, fertilizers, and industrial chemicals.

Ready to improve your crystallization process? Contact our team today to discuss engineered solutions tailored to your industry needs.