The AOD converter remains the cornerstone of stainless steel and specialty alloy production. While electric arc furnaces provide the initial melt, it is the argon oxygen decarburization (AOD) step that determines carbon content, chromium retention, and final steel quality. Current global market drivers—from decarbonization mandates to increasing demand for high-performance stainless—are forcing producers to evaluate whether to revamp existing converters or invest in new builds.

This guide provides a structured playbook for steelmakers, plant engineers, and operations managers evaluating their options. We cover vessel design, trunnion and drive systems, tuyere and lance design, heat and mass balance fundamentals, automation, refractory wear, revamp triggers, and route selection between AOD and VOD. Throughout, we emphasize practical KPIs, ROI models, and Whiting’s legacy expertise in North American AOD converter projects.

What is an AOD Converter and Where It’s Used

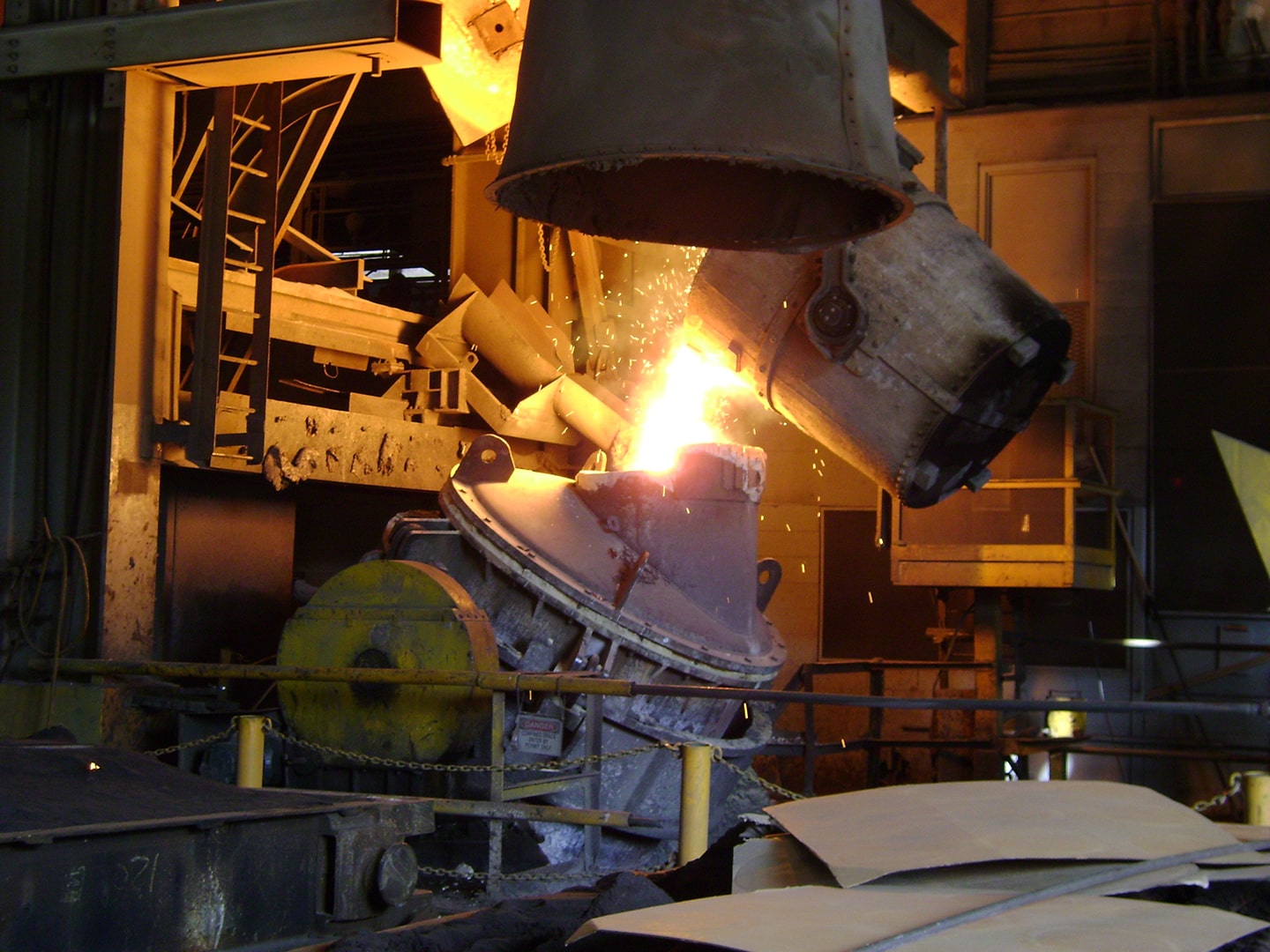

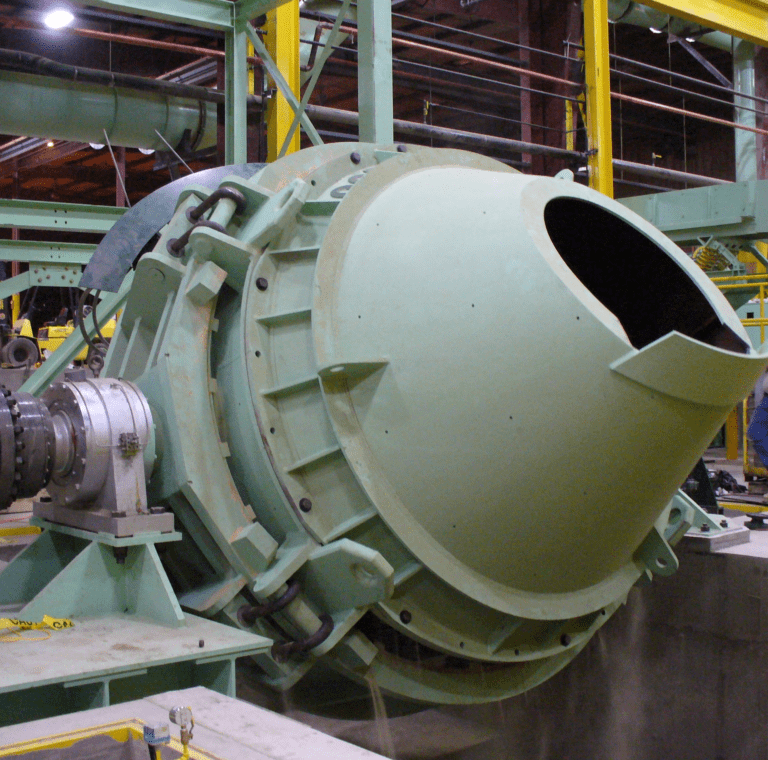

An AOD converter is a specialized refining vessel used after the initial steel melt, typically from an electric arc furnace. Its primary role is decarburization—reducing carbon content to the very low levels required for stainless steel—while minimizing chromium oxidation.

Applications include:

- Stainless steels: The majority of global stainless output passes through an AOD.

- High-alloy steels: Tool steels, superalloys, and corrosion-resistant grades benefit from precise carbon and nitrogen control.

- Ferroalloy refining: Certain ferrochrome and ferronickel operations also use AOD principles.

Due to this flexibility, AOD refining has become the dominant route for producing stainless steel worldwide. Compared with EAF-only processes, AOD achieves higher chromium yields, better nitrogen control, and lower alloying costs—critical factors for competitive stainless producers.

Vessel & Trunnion Basics

The converter vessel is at the heart of the process, and its design has a direct impact on reliability and throughput.

- Vessel geometry: Designs vary from 1-ton foundry converters to vessels exceeding 150 tons. Geometry affects gas distribution, bath mixing, and refractory wear.

- Trunnion systems: Heavy-duty trunnions support vessel rotation for charging, refining, and tapping. Wear in trunnion bearings or misalignment is a common maintenance issue.

- Drive and tilt upgrades: Modern converters are starting to utilize hydraulic or variable-frequency-controlled electric drives for tilt control. Safety PLCs prevent over-rotation or uncontrolled tilts, protecting both equipment and operators.

Gas Mixing & Lance Design

The defining feature of an AOD converter is its controlled gas injection system. Without adequate mixing, operators risk uneven reactions, poor decarburization efficiency, and unnecessary alloy losses.

- Tuyeres: Nozzles embedded in the vessel lining inject oxygen, nitrogen, and argon into the molten bath. Placement and design are critical—poor distribution leads to uneven reactions and higher refractory wear.

- Tuyere clogging: A common issue in older vessels. Solutions include optimized nozzle angles, improved cooling, and better purge practices.

- Lances: Top-blowing lances supplement tuyere injection, allowing for more flexible control of oxygen/nitrogen mixing, as well as decarburization rates.

- Gas ratios: Early stages use higher oxygen to remove carbon quickly; later stages favor argon/nitrogen to limit chromium oxidation.

Nitrogen and Carbon Control Levers

One of the key advantages of the AOD converter process is its ability to fine-tune both nitrogen and carbon levels in stainless and specialty steels.

- Carbon control: Decarburization must be carried out aggressively in the early blow to reduce carbon content rapidly, but the rate must be moderated in later stages to avoid chromium oxidation. Operators typically use stepped oxygen/argon ratios, starting with high oxygen percentages and gradually increasing inert gas dilution as carbon falls below 0.1%.

- Nitrogen control: While nitrogen can be used to dilute oxygen and protect chromium, excess nitrogen absorption leads to brittleness in many grades. Careful lance and tuyere design, along with late-stage argon flushing, helps keep nitrogen pickup within acceptable limits.

- Trade-offs: Aggressive decarburization shortens cycle times but increases alloy recovery costs, while conservative blowing improves yield but extends the tap-to-tap time. Experienced operators and well-tuned automation strike the balance that optimizes both economics and quality.

This dual control of carbon and nitrogen is what makes the AOD converter indispensable for stainless producers competing on alloy efficiency.

Heat & Mass Balance Essentials

Refining in an AOD converter is a balance of thermodynamics and economics. Operators must weigh decarburization speed against alloy retention and energy balance.

- Decarburization: The primary goal is to lower carbon content to <0.05%. Oxygen reacts with carbon to form CO, but excess oxygen also oxidizes chromium, increasing alloying costs.

- Chromium retention: Argon and nitrogen dilution reduce the oxygen partial pressure, suppressing chromium oxidation. Retaining even 1–2% more chromium significantly lowers ferrochrome additions later.

- Nitrogen pickup: Careful control of gas ratios prevents excessive nitrogen absorption, critical for high-purity grades.

- Energy balance: Oxygen reactions are exothermic, contributing heat to the bath. Proper balancing reduces external energy inputs.

An optimized heat and mass balance directly lowers alloying and energy costs while ensuring steel meets demanding specifications.

Automation & Interlocks

Automation has become a defining factor in modern AOD converter operation. The complexity of controlling multiple gases, lance positioning, and tilt angles makes manual-only systems impractical for competitive operations.

- PLCs and SCADA systems: Manage gas flow, tilt angle, lance position, and cooling.

- Safety interlocks: Protect against overpressure, gas mis-sequencing, or unsafe tilt conditions.

- Signal filtering: Digital systems reduce noise, improving accuracy in gas flow and pressure control.

- Integration with plant MES: Links converter performance directly to melt-shop KPIs, such as tap-to-tap cycle time and alloy yield.

Plants that have invested in automation upgrades typically report shorter and more consistent cycle times, fewer safety incidents, and longer refractory campaigns.

Refractory, Wear & Safety

Refractory performance is one of the most significant cost factors in AOD converter operation, with direct implications for safety and operational efficiency.

- Wear hotspots: Tuyere banks, slag line, and trunnion areas typically fail first.

- Monitoring methods: Laser scanning and online thermography provide early warning of thin spots.

- Safety practices: Current technology designs incorporate remote operation stations, improved operator shielding, and PLC-controlled emergency tilt functions.

By proactively monitoring wear and investing in remote safety systems, operators can extend refractory campaigns and reduce risks to personnel working near the vessel.

Revamp Triggers & ROI

Deciding when to revamp is as essential as choosing the right equipment. Signs that an AOD converter needs attention include declining throughput, increasing alloy consumption, or frequent unplanned outages.

Common triggers:

Beyond the obvious mechanical and refractory concerns, revamps are often triggered by regulatory and customer-driven pressures. Emissions rules in North America and Europe are tightening, and older converters with inadequate off-gas handling may require upgrades to maintain operating permits. Similarly, customers in the automotive and appliance markets are increasingly demanding detailed carbon footprint reporting. Melt shops unable to demonstrate efficiency improvements risk losing contracts, making revamp projects a strategic necessity rather than just an operational choice.

ROI considerations:

- Improving tuyere systems often can pay back in a relatively short period of time by reducing alloy losses.

- Automation upgrades can extend useful converter life while improving KPIs.

For plants facing stainless demand growth, ROI models often favor revamps as the first step, with new builds reserved for major expansions.

AOD vs VOD: Route Selection

While the AOD converter dominates stainless refining, vacuum oxygen decarburization (VOD) is a viable alternative for specific products.

- AOD strengths: High throughput, lower cost per ton, good chromium retention, and broad alloy flexibility.

- VOD strengths: Ultra-low carbon levels (<0.01%) and very low nitrogen steels. Ideal for high-purity alloys and specialty grades.

- Route selection: Plants producing standard stainless grades often favor AOD. Those requiring ultra-low carbon or nitrogen contents may opt for VOD or AOD+VOD hybrid routes.

This route selection framework helps melt shops align process design with market requirements, balancing CAPEX, operating costs, and product mix.

Capex vs Throughput Models

When evaluating new builds versus revamps, decision-makers must weigh capital expenditure (CAPEX) against long-term throughput potential.

- Revamp projects: Lower initial investment, faster implementation, and immediate improvements in energy efficiency and alloy yield. However, the vessel’s ultimate size and geometry remain fixed, limiting future scalability.

- New builds: Higher CAPEX but provide opportunities for larger vessel sizing, optimized trunnion systems, and state-of-the-art automation. These designs typically deliver longer campaign lives and can handle higher annual tonnage.

- Throughput models: A common rule of thumb is that new builds justify their cost when throughput demands are expected to increase significantly over current capacity. For smaller incremental gains, revamps provide superior ROI.

By modeling both CAPEX and throughput scenarios, operators can align investment decisions with market forecasts, ensuring the chosen path maximizes profitability and long-term competitiveness.

Conclusion

The AOD converter remains the backbone of stainless and specialty steel refining. But the demands of today’s market—higher throughput, stricter emissions standards, and tighter alloying economics—require modern vessels and intelligent upgrade strategies.

Whiting’s North American legacy in converter design and revamps positions us as a trusted partner for melt shops facing these challenges. If your priority is extending campaign life or modernizing automation, Whiting can help you by partnering with the market’s best in-field companies or evaluating a full new-build investment by delivering in-house engineering expertise and ROI-driven solutions to keep your operation competitive.

Partner with Whiting to assess your AOD converter systems, identify revamp triggers, and plan new builds that align with your throughput and sustainability goals.

FAQ & Spec Checklist

When evaluating revamps or new builds, operators consistently ask the same questions:

What are the typical vessel sizes for AOD converters?

From 1-ton foundry converters to >150-ton mill vessels

What are common revamp priorities?

While refractory improvements can enhance your yield, automation modernization can increase your yield. Maintaining your AOD’s components, such as the drive system, platforms, and alloy add systems, will help you maintain your capacity by increasing your uptime.

These questions form a practical checklist for any plant preparing to assess revamp proposals or spec a new converter build.