Falling‑Film vs Forced‑Circulation Evaporators: Which for Scaling Brines?

Falling-Film vs Forced-Circulation: Selection Guide Selecting the right industrial evaporator can make the difference between smooth, cost-efficient processing and persistent fouling issues. In industries that deal with scaling brines—particularly those involved in lithium production from high-chloride sources—making the correct choice between falling-film vs forced-circulation evaporators is crucial. Both designs are proven technologies, but each behaves […]

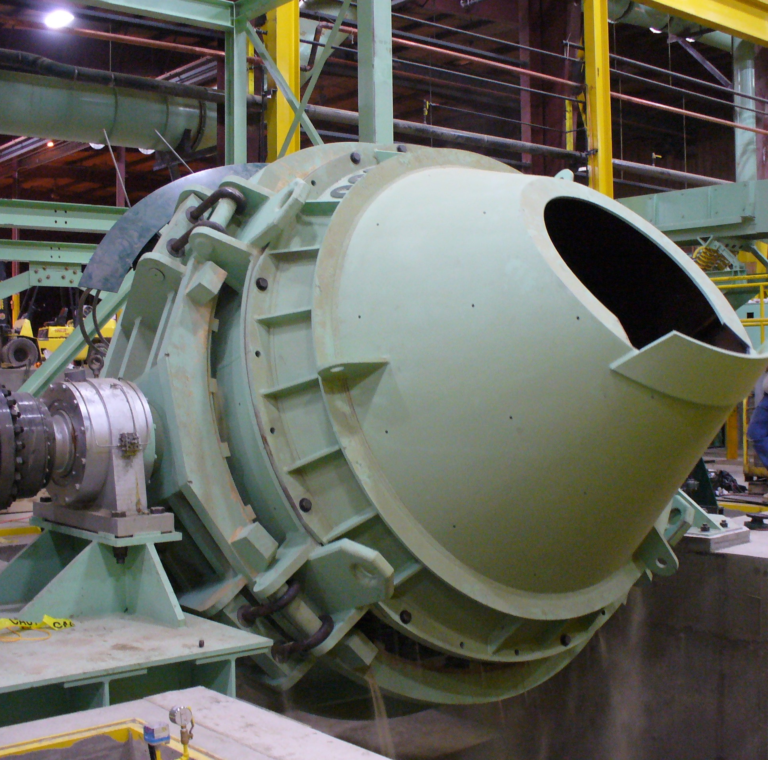

DTB vs Forced Circulation Crystallizer: Which Design Is Best When?

Crystallizer Type Comparison & Selection Choosing the right crystallizer design is never a one-size-fits-all decision. Each type has unique strengths, making it better suited for specific materials, operating conditions, and purity goals. Among the most widely discussed are Forced Circulation (FC) and Draft Tube Baffle (DTB) crystallizers. Forced Circulation (FC) crystallizers are workhorses built for high solids […]

EAF Electrode Regulation: Cut Power-On Time Without Blowing Your Arc

Introduction In any electric arc furnace (EAF), productivity hinges on electrode performance. Operators know that uncontrolled arcs don’t just waste energy—they destroy electrodes, damage refractories, and extend tap-to-tap cycles. The difference between a furnace that consistently meets production targets and one that often lags comes down to one system: EAF electrode regulation. When tuned correctly, […]

AOD vs VOD: Which Refining Route Fits Your Grade Mix?

Introduction In stainless steel and specialty alloy production, refining technology not only determines quality but also significantly impacts cost efficiency and competitiveness. Two refining routes dominate today’s market: the AOD converter (argon oxygen decarburization) and VOD (vacuum oxygen decarburization). Both are proven technologies, but they serve different purposes depending on the grade mix, the required […]

Ladle Preheat Stations: Fuel Choices, Emissions & Lining Life

Designing Ladle Preheat Stations Preheating isn’t optional—it’s essential. A ladle preheat station directly influences lining life, tap-to-tap time, casting quality, and safety. Improperly dried or inadequately heated linings cause thermal shock, shortened refractory life, inclusions, steam explosions, and out-of-spec heats. The right system design ensures consistent thermal profiles, fewer relines, and predictable performance across every […]