AOD Tilt/Drive Upgrade Guide

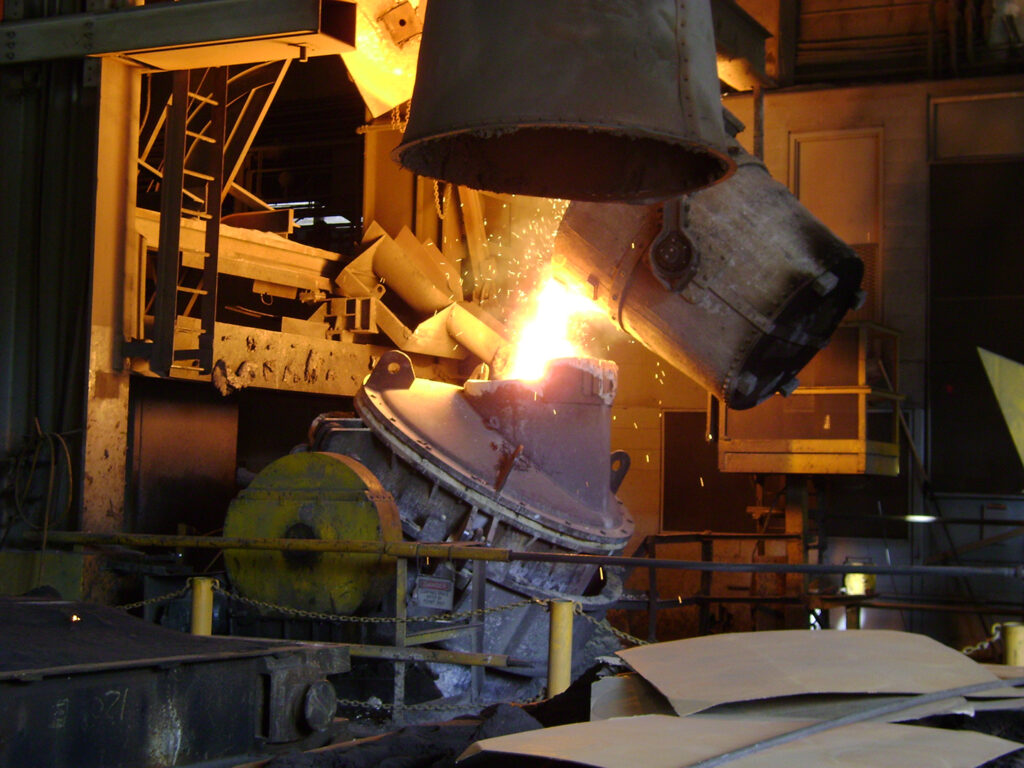

Tilting is one of the highest-risk, highest-uptime-impact functions in an argon-oxygen decarburization (AOD) converter. Every heat requires precise, smooth, and reliable tilt control for blowing, sampling, temperature checks, slag removal, and tapping. A single failure in the tilt system can stop production instantly—and when a vessel is full of molten steel, it becomes a critical safety event, not just a maintenance inconvenience.

Modernizing the tilt and drive system is one of the most effective ways to improve safety, uptime, and lifecycle costs for AOD operations. This article outlines the key components of a successful AOD converter tilt drive upgrade, including tilt system designs, redundancy, safety interlocks, expected downtime, and ROI considerations.

Tilt System Types: Mechanical vs. Electro-Hydraulic

AOD converters traditionally use mechanical tilt drives, but electro-hydraulic solutions are increasingly used in modern or retrofitted shops. Each has trade-offs:

1. Mechanical Tilt Systems (as in your supplied design)

- Heavy-duty helical gear, dual-input, single-output design.

- Power transmitted via a parallel shaft gear reducer with gear coupling.

- Best known for durability and stable motion control.

- Ideal for large converters and shops prioritizing long equipment life.

2. Electro-Hydraulic Tilt Systems (industry-standard alternative)

- Use hydraulic cylinders or rotary actuators for tilt motion.

- Faster response and higher precision for fine-angle adjustments.

- More sensitive to hydraulic fluid cleanliness and temperature control.

Industry note: Most steelmakers retain mechanical tilting for AOD due to its reliability in high-heat, high-vibration environments, and because hydraulic leaks around molten steel pose avoidable risks.

Failure Modes That Drive Upgrade Decisions

Tilt systems endure some of the harshest working conditions in a melt shop—heat, slag splash, dust, vibration, and high torque loads. Common failure drivers include:

- Gear reducer wear and backlash create inconsistent tilt control.

- Motor failure, especially without redundancy.

- Encoder/sensor drift, leading to inaccurate tilt angles.

- Brake malfunction, creating “uncommanded movement” risk.

- Coupling misalignment causes vibration and accelerated bearing failure.

A well-scoped upgrade addresses not just the drive components, but the entire ecosystem of sensors, controls, brakes, and backup systems.

Safety Interlocks, Redundancy & Motion Control

Safety is the most critical reason melt shops choose to upgrade their AOD tilt and drive systems. A converter filled with molten steel must maintain controlled motion at all times—especially during tapping, when the vessel is at its most vulnerable. In one configuration delivered by Whiting, the system was powered by two 52.5 hp DC mill motors, providing both the torque and stability needed for smooth operation. Tilt speed was fully variable from 0 to 1 rpm, allowing operators to make precise adjustments during blowing, sampling, slag removal, and tapping.

To prevent loss of control in the event of a power failure, the system incorporated two nitrogen-driven backup motors. This redundancy ensured that the vessel could still be tilted to a safe position if the primary drive were to fail. Together, this dual-motor and dual-backup design created multiple layers of protection, ensuring reliable, controlled movement under all operating conditions.

Modern safety upgrade practices include:

- Safety-rated PLC with dual-channel tilt permissives.

- Independent hardwired tilt-stop circuit separate from the process PLC.

- Shaft- or motor-mounted absolute encoders for position verification.

- Brake-set confirmation sensors to prevent “tilt on brake applied” faults.

Sensors, Encoders & Health Monitoring

To avoid catastrophic failures, shops are layering in condition monitoring and digital diagnostics:

| Component | Modern Upgrade Best Practice |

| Tilt Position | Absolute encoder + secondary limit switches |

| Drive Health | Motor temperature, vibration, and current draw monitoring |

| Gear Reducer | Oil temperature + metal-particle debris sensors |

| Backups | Weekly auto-test routines to verify nitrogen drive functionality |

The goal is early warning of wear, long before tilt drift or torque spikes occur.

Upgrade Scope & Expected Downtime

A typical AOD converter tilt drive upgrade which can be managed efficiently through Whiting Services includes some or all of the following:

- Replacement or overhaul of gear reducer + coupling.

- Motor upgrades (often AC + VFD replacement instead of DC drives).

- New brake assemblies and fail-safe logic.

- Redundant encoders and tilt-limit safety switches.

- Safety-rated PLC and updated HMI controls.

- Backup drive verification or replacement.

Typical downtime window:

- Minor upgrade: 24–48 hours.

- Full mechanical replacement + controls upgrade: 5–10 days (often timed with a relining). Remember, Handling Specialty’s Relining Ladle platform lifts are the preferred material handling equipment when relining or rebricking your steel ladle.

Because the vessel mounting design enables vessel exchange in under one hour, many shops synchronize tilt upgrades with pre-planned vessel swaps to avoid added production loss.

ROI: Where the Payback Comes From

Tilt upgrades rarely depend on energy savings—they pay for themselves through risk reduction and uptime gains. Common ROI drivers include:

- Fewer unplanned stoppages due to tilt or brake faults.

- Safer tap control, reducing spills and product quality loss.

- Reduced gear reducer rebuild frequency.

- Lower maintenance man-hours through diagnostic monitoring.

- Improved operator control and positional accuracy.

Most upgrades deliver a payback in 12–24 months, depending on vessel size and campaign volume.

Spare Strategy

A smart spare strategy keeps critical tilt components on hand so a single failure cannot take the converter offline:

- One complete backup tilt motor (or matched pair for dual drives).

- Encoder + limit switch kit.

- Brake pads and solenoid valves.

- Gearbox seal kit and oil supply.

For nitrogen backup drives, periodic readiness testing and cylinder inventory tracking are essential. You can contact Whiting Equipment Canada’s Service department anytime to order parts or Planned Maintenance.

Final Thoughts

A reliable tilt system is non-negotiable for both uptime and molten-metal safety. Upgrading the drive, controls, and backup architecture for your AOD converter significantly reduces operational risk, prevents unplanned outages, and provides a stronger safety envelope for operators. Talk with our team to learn more about how we approach an AOD converter tilt drive upgrade.