For decades, steelmakers have debated whether AC or DC EAF systems deliver the best return on investment. In 2025, that question is no longer theoretical—it’s a financial and operational decision shaped by power quality regulations, electrode costs, and automation readiness. Both technologies have matured, but their strengths diverge in subtle ways that matter when planning an expansion or retrofit.

Technology Overview

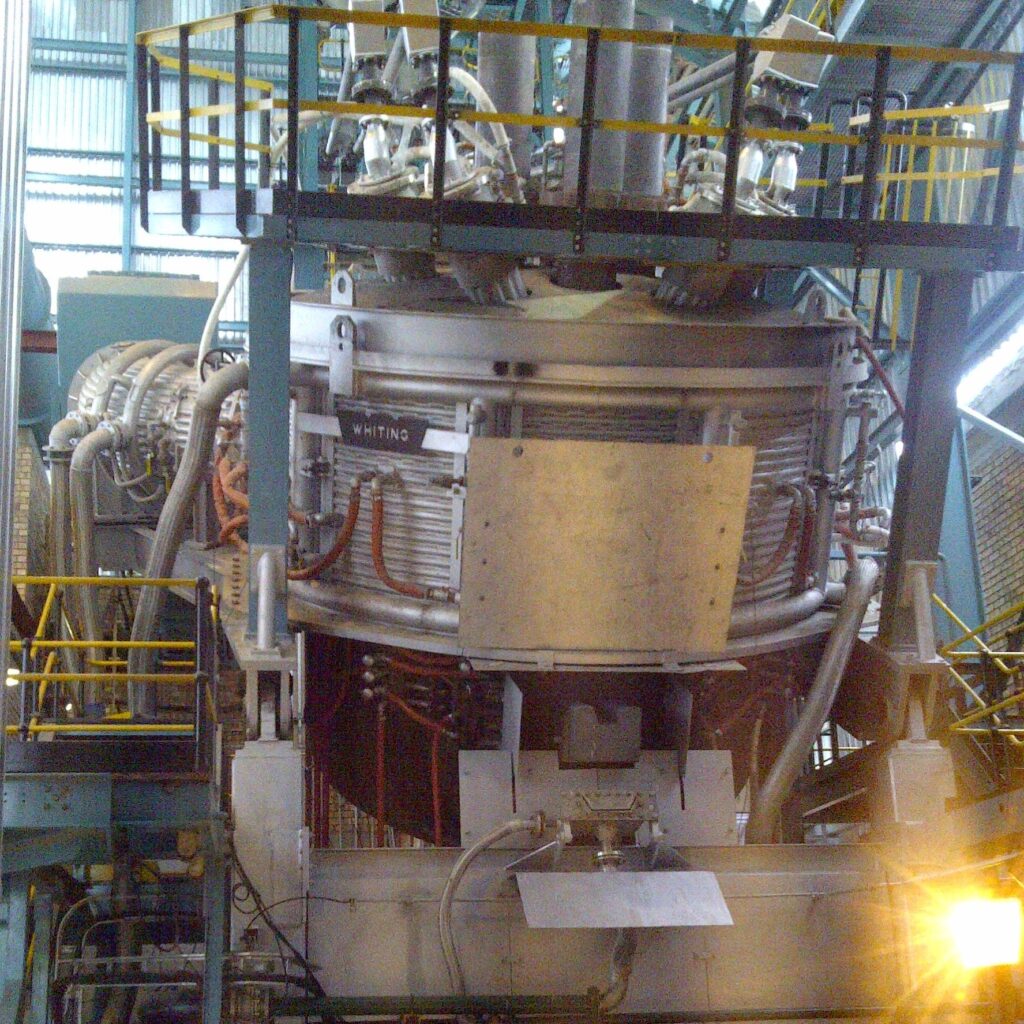

An Electric Arc Furnace (EAF) converts electrical energy into the thermal energy required to melt scrap or direct-reduced iron (DRI).

- AC EAFs use three graphite electrodes in a Y-phase configuration. They dominate globally due to proven reliability, lower capital cost, and easier maintenance.

- DC EAFs use a single graphite electrode (cathode) with the furnace bottom acting as an anode. The current path is more straightforward, reducing electrode consumption and flicker, but DC systems require large rectifiers and bottom-anode maintenance.

Whiting Equipment Canada supports both configurations. Its Hydro-Arc® and custom EAF designs use water-cooled shells, low-impedance transformers, and Volta-SAF Regulators—control systems that deliver high-response arc stability for either AC or DC installations.

Capex / Opex Comparison

AC EAFs generally win on Capex. The power supply and transformer arrangement are simpler, and spare parts are widely available. Maintenance teams already know the architecture, which keeps operating costs predictable.

DC EAFs, by contrast, often win on Opex where power tariffs are high or electricity quality penalties apply. Single-electrode operation lowers electrode consumption by 25–40 % (industry-typical range) and cuts noise and flicker at the transformer. However, rectifiers and bottom electrodes add up-front cost and occasional maintenance complexity.

Over a 10- to 15-year asset life, the total cost difference narrows. Plants with high power quality penalties or premium electrode pricing can offset DC’s capital premium within a few years.

Electrical Quality: Flicker & Harmonics

Power quality remains the headline reason to consider DC. The steady current path produces fewer voltage dips and harmonic distortions, an advantage in regions where grid operators enforce strict flicker limits.

Modern AC EAFs have closed much of that gap. Whiting’s Volta-SAF digital regulator and Norsk Trafo Service transformers achieve low-impedance power transfer, reducing arc instability and minimizing flicker. Shell-type furnace transformers—favored for their one-half to one-third lower reactance—help stabilize arcs and limit utility complaints.

For plants operating under sensitive utility contracts, the decisive factor is often not AC versus DC but the sophistication of arc control. A modern AC EAF with a high-speed regulator can now meet many of the same grid-compliance thresholds as older DC units.

Operational Considerations

DC EAFs typically run quieter with a more stable arc, resulting in lower refractory wear and slightly faster meltdown time. Their single electrode simplifies scrap charging geometry and improves furnace accessibility.

AC EAFs, however, remain more forgiving. With three electrodes, operators can balance uneven scrap loads and maintain throughput even when one phase experiences instability. Electrode replacement is faster, and spare parts are common.

From a maintenance perspective, DC bottom-anode replacement is the primary downtime driver, while AC systems face routine electrode and contact-clamp wear. Both benefit from improved water-cooled panels and automated regulation that protects refractories from localized over-arc exposure.

Upgrade & Migration Paths

Whiting’s approach to retrofits supports either migration direction. The Volta-SAF Regulator uses fiber-optic links to both DC and Direct Torque Control (AC) drives, allowing hybrid or staged upgrades.

Many legacy AC shops now adopt partial DC conversions—such as single-phase DC boosters—to gain some flicker reduction without replacing the entire power island. Conversely, DC plants modernize by adding new transformer sets and higher-frequency regulators to shorten tap-to-tap times.

A Whiting-engineered retrofit can often reuse the shell, transformer, and hydraulic systems while upgrading the drive train and control logic. That minimizes downtime and capital exposure.

When DC Still Wins

DC EAFs continue to make sense where:

- Grid connection fees or flicker penalties are high.

- Electricity reliability is stable (no frequent outages).

- Large single-charge heats justify longer campaign times.

- Bottom-anode maintenance can be scheduled efficiently.

For boutique stainless or specialty steel operations seeking extremely clean melts and minimal power-factor disturbance, DC remains the preferred configuration.

Utility Constraints and Power Contracts

Utilities now price in voltage stability. AC plants may face higher reactive-power charges if they lack flicker compensation. Installing static VAR compensators (SVCs) or active filters narrows that gap but adds cost. DC furnaces that draw smoother current often meet contractual limits without auxiliary compensation equipment—a meaningful advantage in regions with energy-intensive tariffs.

Retrofit Considerations & ROI

When evaluating a conversion or upgrade:

- Assess transformer condition—modern shell-type transformers can often be retained.

- Review electrode consumption history—if consumption exceeds industry averages, DC conversion or regulator upgrade may yield quick ROI.

- Evaluate downtime tolerance—AC retrofits are generally faster; DC installations require rectifier commissioning and ground-return testing.

- Quantify grid penalties—utility fees may justify switching even if capital is higher.

A staged modernization—beginning with control and regulator upgrades—often delivers 60–70% of DC’s performance benefits without changing the power configuration.

The Bottom Line for 2025 and Beyond

AC EAFs dominate due to their simplicity, lower capital costs, and universal serviceability. DC EAFs retain their edge in environments where power quality and electrode consumption drive economics.

The deciding factors are no longer the current type—it’s control precision, transformer design, and integration strategy. For many producers, upgrading regulatory systems and water-cooled structures provides a higher ROI than switching furnace polarity.

If your melt shop is evaluating an AC vs DC EAF path, Whiting’s engineers can model your specific power contract, duty cycle, and capacity goals to identify the most cost-effective configuration—whether that means smarter AC regulation, a hybrid DC conversion, or a complete modernization program. Contact us to discuss your requirements.