Crystallizer Type Comparison & Selection

Choosing the right crystallizer design is never a one-size-fits-all decision. Each type has unique strengths, making it better suited for specific materials, operating conditions, and purity goals. Among the most widely discussed are Forced Circulation (FC) and Draft Tube Baffle (DTB) crystallizers.

- Forced Circulation (FC) crystallizers are workhorses built for high solids concentrations. They circulate mother liquor at high velocity through a heat exchanger, preventing solids from settling and reducing fouling. This makes them ideal when throughput and reliability are most important.

- DTB crystallizers shine when crystal size distribution (CSD) is critical. Their draft tube and baffle system separates smaller fines from larger crystals, allowing the latter to keep growing. They’re used when consistency and narrow particle ranges drive downstream performance.

The choice between these types ultimately depends on your material properties, quality requirements, and economic drivers.

Quality & Yield Outcomes

At the core of crystallization lies product quality. The more control you have over crystal growth, the more predictable and marketable the outcome will be.

- DTB crystallizers excel in creating a narrow CSD, reducing fines, and ensuring higher uniformity. This matters in industries such as battery materials or specialty chemicals, where particle size can significantly impact performance.

- Forced Circulation crystallizers tend to produce a broader range of crystal sizes. Still, their efficiency and ruggedness make them attractive for bulk products where precise sizing isn’t as critical as maximizing yield.

Across all three industrial crystallizers, purity goals can be met by carefully managing supersaturation, residence time, and agitation. Pilot testing is often the decisive step in aligning each design with a product’s target yield and quality metrics.

Energy & Fouling Tendencies

Energy use and fouling are two of the most significant operational costs in crystallization.

- FC crystallizers are specifically engineered to fight fouling. The high-velocity circulation prevents solids from depositing in the heat exchanger, thereby extending uptime and enhancing heat transfer efficiency.

- DTB crystallizers require more careful management of scaling and fouling since their internal zones are more complex. However, the reward is tighter control over particle size.

When fouling is a constant headache, Forced Circulation usually comes out ahead.

Footprint & Complexity

Every plant faces space constraints and design limitations.

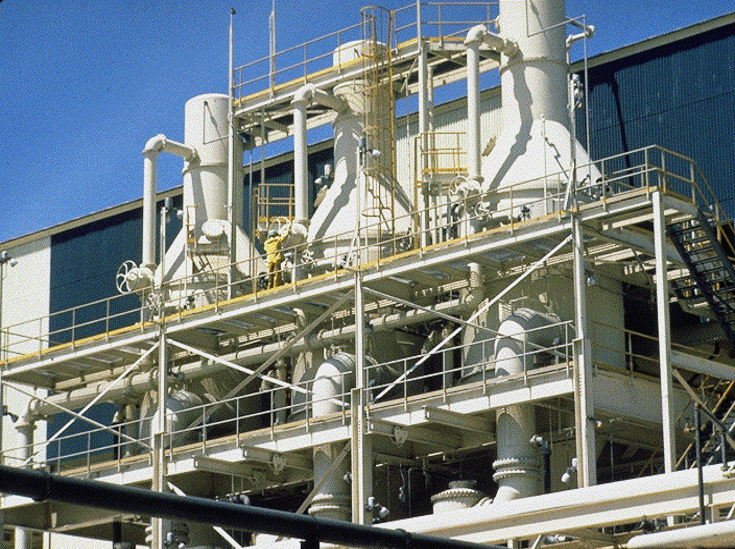

- Forced Circulation crystallizers are mechanically simpler, but their large pumps and external heat exchangers can increase footprint.

- DTB crystallizers require more internal components (draft tube, baffle, classification zones), adding design complexity but often compacting the growth and separation into one vessel.

The deciding factor often comes down to how easily each design can be integrated into an existing layout — something where engineering experience plays as big a role as the equipment itself.

Decision Matrix

So, when should you choose DTB vs forced circulation crystallizer? Here’s a practical way to think about it:

- If you need high throughput with tough feeds → go with Forced Circulation. They’re rugged, handle slurries well, and resist fouling.

- If you need tight control over particle size → choose DTB. Their internal classification delivers narrow CSDs perfect for high-value, quality-driven products.

In practice, the “best” crystallizer is rarely chosen by type alone. Pilot testing, impurity profiles, and end-product requirements all inform the final decision.

When Hybrids Work

Sometimes, the solution isn’t strictly one type or another. Hybrid systems can blend the strengths of different designs — for instance, an FC crystallizer with added classification features from a DTB. With modern modeling and pilot facilities, engineers can tailor hybrid configurations that optimize yield, purity, and operating costs.

Upgrade Paths

A crystallizer is a long-term investment, and the flexibility to upgrade is critical. Control systems can be modernized with modular hardware and advanced monitoring, thereby extending efficiency without requiring the replacement of the entire unit. Mechanical upgrades — from heat transfer surfaces to internal baffling — can also help existing units match today’s process demands. By planning for staged upgrades, operators protect their initial investment while keeping pace with evolving product and market requirements.

Conclusion

Choosing between DTB vs forced circulation crystallizer designs isn’t about declaring a universal winner — it’s about matching each system to your goals. If fouling resistance and high throughput are paramount, FC shines. If you’re chasing narrow particle ranges, DTB leads. With the Whiting team guiding modeling, pilot testing, and design, you can confidently select — or even customize — the crystallizer that ensures quality, efficiency, and profitability. Contact us for an initial, no obligation conversation.