Designing Ladle Preheat Stations

Preheating isn’t optional—it’s essential. A ladle preheat station directly influences lining life, tap-to-tap time, casting quality, and safety. Improperly dried or inadequately heated linings cause thermal shock, shortened refractory life, inclusions, steam explosions, and out-of-spec heats. The right system design ensures consistent thermal profiles, fewer relines, and predictable performance across every heat.

This guide outlines fuel choices, heating profiles, emissions, safety components, and instrumentation considerations when specifying a high-performance ladle preheat station for melt shops and AOD operations.

Burner & Fuel Options

A modern ladle preheat station must balance fuel availability, heat-up time, emissions, and operating cost. Systems are typically configured with low-pressure gas or oil burners, with two combustion-air delivery options:

Fuel Types

• Natural gas or fuel oil

• Low-pressure burner designs

Combustion Air Systems

| System | Description | Notes |

| GB – Blower Type | Turbo blower with TEFC motor supplies combustion air | Good for consistent high heat |

| GI – Inspirator Type | Uses compressed plant air via an inspirator | Lower install complexity |

When ordering, operators must specify: heater type (GB or GI), fuel (gas or oil), electrical characteristics, and altitude (required when >500 ft above sea level).

Standard Swivel-Type Preheater Models

(All support gas or oil)

- GB #1 OB / GI: 29″–36 ½” ladles

- GB #2 OB / GI: 40 ½”–46″

- GB #3 OB / GI: 48 ½”–58″

- GB #4 OB / GI: 62″–72″

- GB #5 OB / GI: 79″–86″

Temperature Profiles & Lining Life Impact

Proper heating and drying of refractory linings have as much effect on casting quality as any other foundry operation. Consistent preheating eliminates moisture, reduces thermal shock, and extends lining campaign life.

Thermal Capacity Ratings:

• Vertical ladle preheater for 70/85-ton AOD system: 7 × 10⁶ Btu/h

• AOD vessel preheater (horizontal): 10 × 10⁶ Btu/h

• Standby vessel preheater (vertical): 10 × 10⁶ Btu/h

General industry practice (contextual note):

• Most melt shops target heat-up rates of 150–300°F/hr for new linings (slower for dry-outs, faster for pre-warm cycles before tap).

• High-alumina refractories benefit from uniform heat distribution to prevent cracking at spalling-risk temperatures (typically 400–800°F zone).

Emissions & Compliance

Ladle heating contributes to local emissions, so preheater design closely aligns with the proper design and implementation of melt shop ventilation systems.

Whiting’s design philosophy flows into the development of our environmental controls on related upstream equipment:

- Alloy addition systems include integrated dust-control systems to minimize particulate release at the Mouth of Furnace (MOFU).

• AOD system fume hood is air-cooled, refractory-lined, and mechanically moves to capture fume during operation.

General industry practice:

• Low-NOx burner configurations are increasingly selected to help operations meet regional emissions limits.

• Shops are shifting toward oxygen-enriched combustion for faster heat-up, but must balance the desire for speed with NOx formation considerations.

Safety, Interlocks & Operator Protection

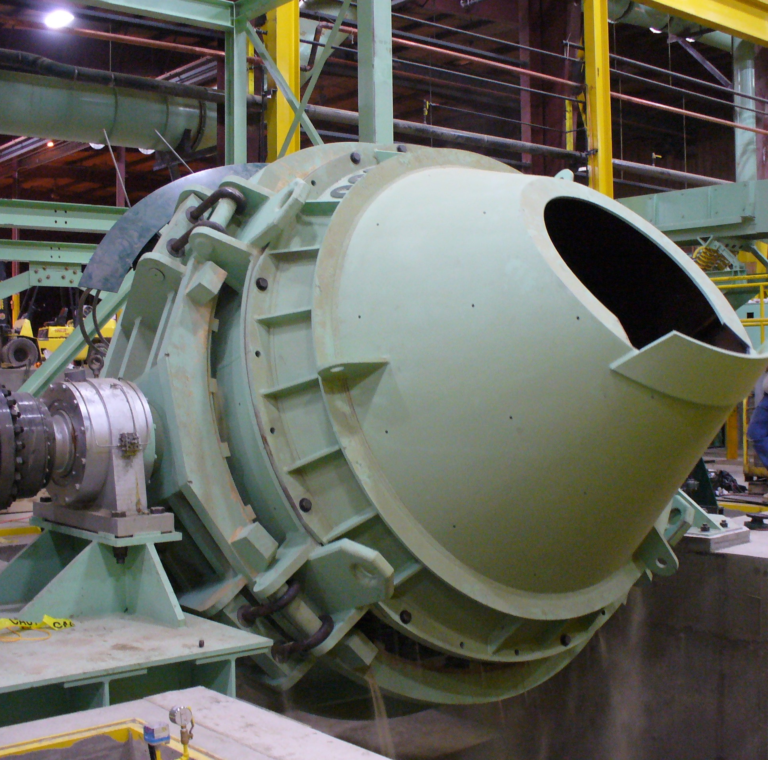

Whiting’s preheaters are designed as swing-type units for safe, ergonomic positioning:

• Floor-mounted mast with pivoting I-beam extension arm

• Arm rotates approximately. 180° for accurate lid-to-ladle alignment

• Fabricated conical cover ensures heat containment and operator shielding

General industry practice (contextual addition):

A modern ladle preheat station typically incorporates:

• Flame-failure detection

• Gas-train safety shutoffs

• Burner permissives tied to cover position, airflow, and ignition status

• Interlocks preventing lift or movement while the burner is active

Instrumentation & Setpoints

Accurate, repeatable heating requires instrumentation capable of maintaining a controlled rate of temperature rise.

Recommended monitoring points (industry standard):

• Ladle wall thermocouples (2–3 locations)

• Burner control (modulating valve)

• Stack O₂ (for combustion tuning)

• Air and fuel pressure switches

Heat-up curves should be logged for QA, maintenance benchmarking, and refractory warranty compliance.

Energy Balance Example

(Values presented below illustrate “how to think” rather than a universal result.)

A 10 × 10⁶ Btu/h vessel preheater running a 45-minute warm-up cycle consumes ~7.5 MMBtu. If natural gas costs $6/ 6/MMBtu, a single preheat costs ~$45. Improving insulation or reducing heat-up time by 10 minutes can save $8–10 per cycle, totaling $25,000–$40,000/year in a 3-shift operation.

Conclusion

A well-engineered ladle preheat station influences nearly every downstream metric—lining life, safety, emissions, tap-to-tap time, and final metal quality. Selecting the right fuel system, heating capacity, controls, and safety interlocks ensures consistency and long refractory campaigns.

If you’re upgrading or specifying ladle or AOD preheating systems, we can help with fuel-system selection, heat-up curves, safety logic, and integration with existing melt-shop controls. Would you like a quick audit to benchmark your current preheat performance and energy usage? Contact us, and let’s have a conversation.