Safety Standards & Interlocks

Mining material-handling systems move hundreds of tons of rock, ore, and concentrate every hour, often through noisy, dusty, and unpredictable environments. Every stop, start, and transfer presents a risk when that much weight is in motion. That’s why mining material handling safety interlocks and related systems are no longer optional—they’re foundational to compliance, uptime, and worker protection.

This post outlines the safety standards, interlock systems, and audit strategies that help operators reduce hazards and meet regulatory requirements across crushing, conveying, and processing lines.

Applicable Standards

Across global mining jurisdictions, equipment safety and interlocking design are guided by overlapping frameworks:

- MSHA (Mine Safety and Health Administration, U.S.) — 30 CFR Parts 56/57/75 establish requirements for guarding, start-up warnings, conveyor controls, and lockout procedures.

- CSA M421 & Z462 (Canada) — govern electrical safety and arc-flash protection in mines.

- ISO 13849-1 / IEC 62061 — define functional safety and performance levels for control systems, particularly for safety-related interlocks and emergency stops.

- ISO 45001 (Occupational Health & Safety Management) — provides the overarching framework for risk management and continual improvement.

For equipment suppliers like Whiting Equipment Canada Inc., adherence to these frameworks ensures every actuator, sensor, and operator interface in a handling system contributes to a traceable safety function rather than an isolated device.

Risk Assessment and Design Integration

A compliant mining-handling system begins with a risk assessment aligned with ISO 12100. Typical hazards include:

- Moving conveyor components and transfer points.

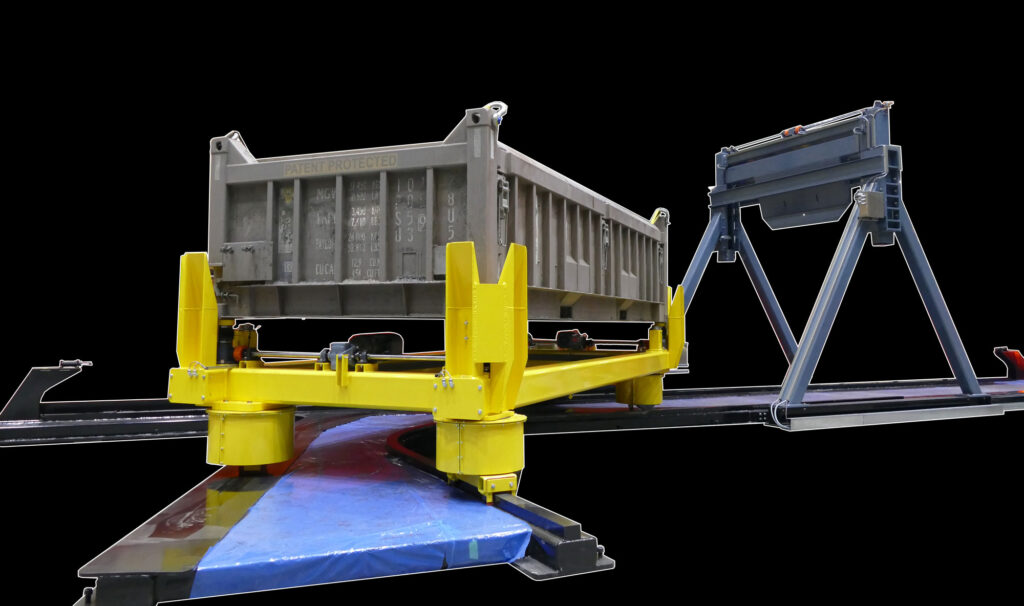

- Uncontrolled motion of railcars, skips, or hoppers.

- Energy isolation failures during maintenance.

- Over-pressure or thermal risks in high-temperature process streams.

Each risk is evaluated for severity, exposure, and likelihood of occurrence and then mitigated through a hierarchy of controls, including design, engineered safeguards, administrative measures, and training.

Modern risk assessments increasingly incorporate digital twins and functional-safety simulations, allowing engineers to test interlock logic and alarm thresholds virtually before commissioning.

Interlocks and Emergency Stops (E-Stops)

Effective mining material handling safety interlocks ensure machinery cannot operate unless all protective barriers, guards, and process conditions are satisfied. Typical examples include:

- Belt conveyor interlocks that verify guarding and tension status before start-up.

- Bucket elevator sensors that halt operation if belt tracking or alignment is lost.

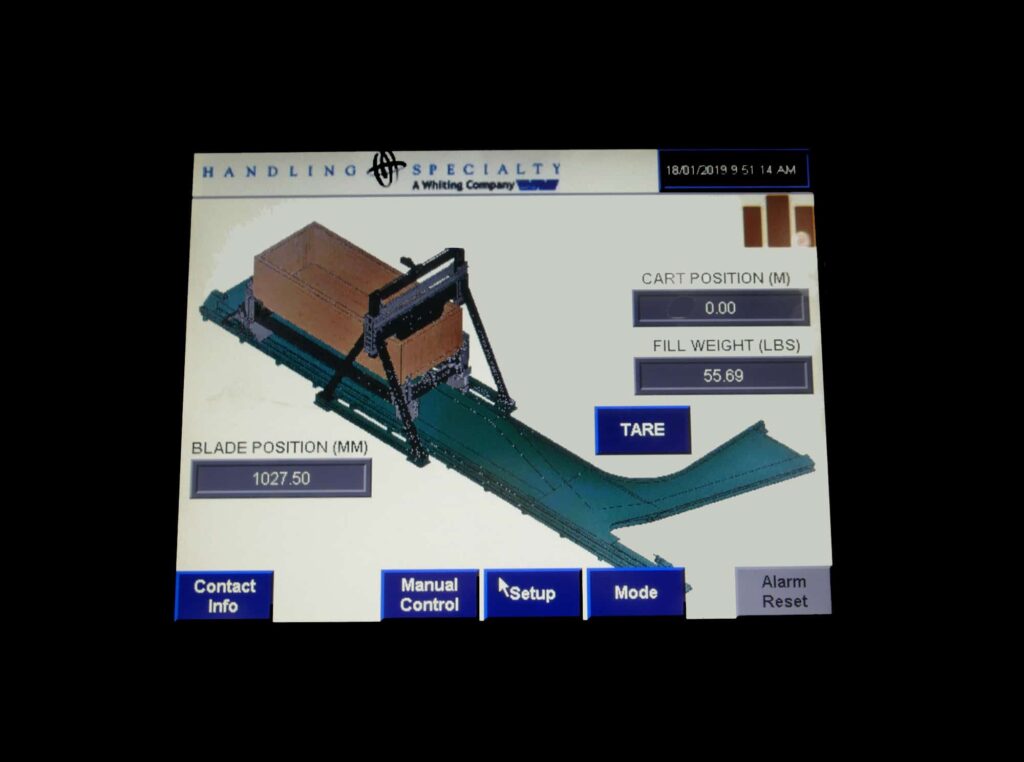

- Crane and transfer car systems with position-sensing and collision-avoidance logic.

Emergency-stop (E-stop) functions, as specified in ISO 13850/IEC 60204-1, must override other functions. After actuation, they require a manual reset, and this reset must not initiate a restart; a restart is a separate, deliberate command. For radio-controlled units (e.g., railcar movers), the E-stop function should be integrated into the certified safety-control architecture (e.g., a safety-rated RF link with a fail-safe design) so that loss of signal brings the machine to a safe state.

The best systems link these interlocks to plant-wide SCADA platforms, providing clear fault messaging—so operators know not just that a stop occurred, but why.

Lockout/Tagout (LOTO) and Training

Even the best-engineered interlocks can’t substitute for disciplined lockout/tagout (LOTO) practices. MSHA and OSHA require all stored-energy sources—electrical, hydraulic, pneumatic, or gravitational—to be physically isolated and tagged before maintenance. Even the best interlocks don’t replace MSHA-required de-energization and blocking procedures (e.g., §§56.12016, 56.12017, 56.14105) before maintenance.

Modern facilities now complement mechanical locks with digital LOTO management systems that track each isolation point via electronic permits. These systems reduce human error and ensure that verification steps are documented in real-time.

Training is equally essential. Every employee involved in equipment operation or maintenance must receive documented instruction on:

- Recognizing energy-isolation points.

- Verifying zero-energy conditions.

- Restarting systems safely after servicing.

Whiting and its affiliates, through ISO 9001:2015–certified designs and conformance to Z299.2 access-equipment standards, emphasize the human-factors aspect of safety—ensuring operators can work at ergonomic heights and with optimal visibility rather than from scaffolds or ladders.

Audit Checklist

A practical audit framework for mining-handling systems should verify the following:

- Functional interlock validation — all safety interlocks verified on a documented, risk-based interval (e.g., monthly or quarterly, depending on criticality and duty cycle).

- E-Stop and alarm functionality — confirmed at operator stations and remote control points.

- Control system documentation — schematics reflect as-built conditions, including any bypasses or overrides.

- LOTO compliance — procedures current, locks uniquely keyed, training up to date.

- Maintenance logs — interlock failures or overrides tracked and reviewed by engineering.

Independent third-party audits, such as those under ISO 45001 (a global OHS management standard, not mining-specific) or equivalent frameworks, remain the gold standard for identifying systemic gaps before regulators do.

Common Gaps and Fixes

Mining audits frequently uncover recurring issues:

- Interlock overrides left in place after commissioning or emergency work.

- Unverified E-Stops following control-system upgrades.

- Lack of redundancy in PLC logic for conveyors handling critical feed streams.

- Incomplete documentation—paper schematics not matching current wiring or code versions.

Fixes often include converting hardwired interlocks to safety-rated PLC inputs, implementing dual-channel circuits, and instituting automatic timestamped logging for all bypass events.

Documentation and Continuous Improvement

Traceability is central to compliance. Every interlock, safety relay, and reset circuit must be captured in:

- Functional-safety documentation (SIL/PL verification).

- Electrical drawings and cause-and-effect matrices.

- Operator manuals and preventive-maintenance schedules.

Leading operators now integrate this data into centralized maintenance management systems (CMMS), linking interlock test results to equipment performance. This helps justify investment in system upgrades and ensures ongoing compliance across inspection cycles.

Conclusion

Mining operations depend on a consistent flow and safe interaction between people and massive equipment. Implementing well-designed mining material handling safety interlocks, supported by rigorous risk assessment and verified documentation, not only protects workers but also prevents costly downtime resulting from avoidable incidents.

If you’re auditing or upgrading your mine’s material-handling safety systems, our engineers can help design compliant interlock architectures and control logic that meet ISO 13849-1 and MSHA requirements—ensuring every ton moved is productive and protected. Contact us to discuss your requirements.