Rotary Dryers

Engineering and Manufacturing Dryers for Chemical Process Industries

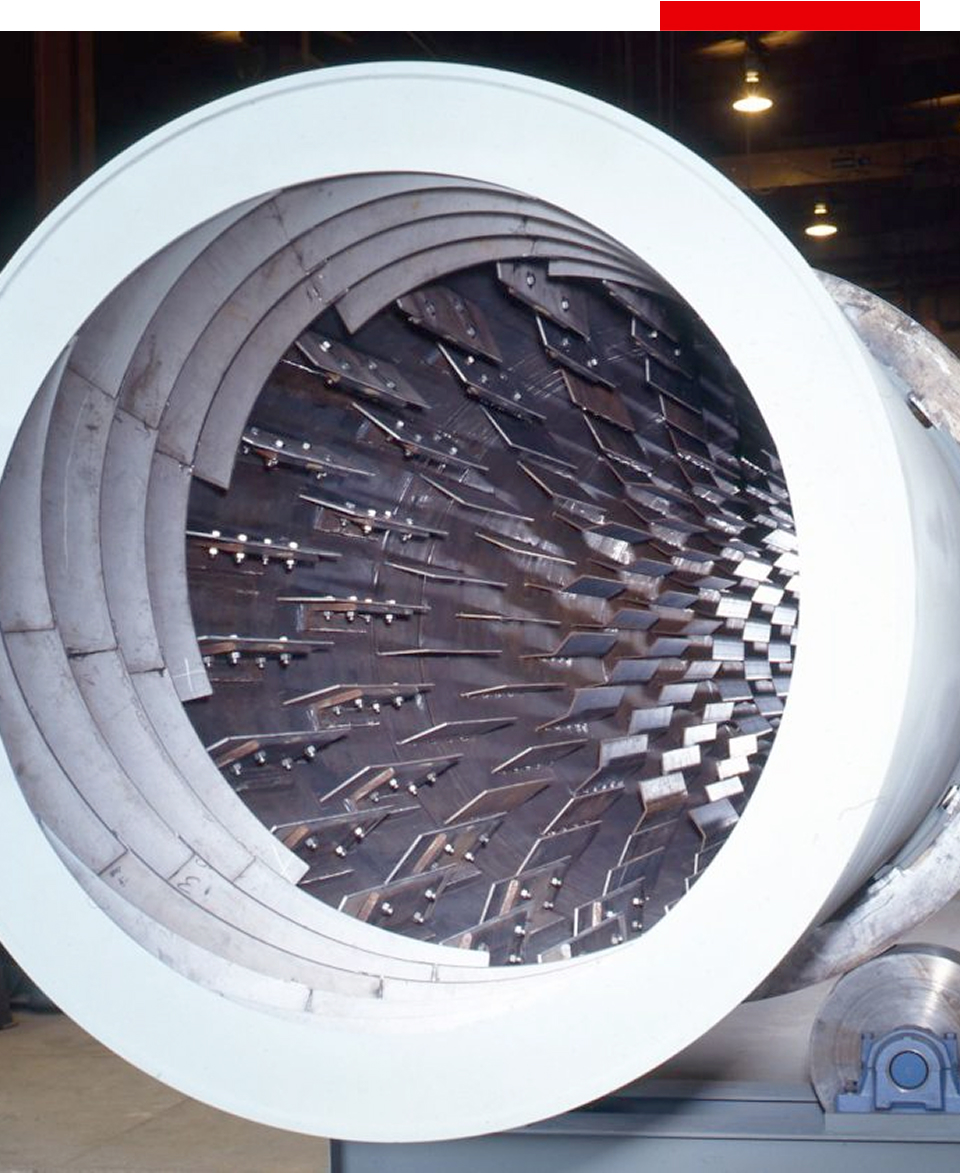

Rotary Dryers

Rotary dryers are a versatile, cost-effective, and efficient solution ideal for drying bulk solids. This drying method is suited to a wide range of applications and is particularly prevalent in the biomass, forestry, and ethanol industries.

Benefits of Rotary Dryers:

- Efficient drying of bulk solids

- Cost-effective and versatile

- Reliable and rugged in harsh conditions, ensuring low-maintenance operation

- Uniform results

- High heat transfer efficiency

- Versatile to meet a wide range of application requirements

How Rotary Dryers Work:

Much like a home clothes dryer, rotary dryers use a rotating drum to tumble product while exposing it to a drying gas such as air. A rotary dryer is used for free-flowing feeds, with a narrow to wide particle size distribution and for both small and large size particles. Wet and pasty materials can be dried when the feed is back-mixed with dry product. Air flow can be parallel or countercurrent to the solids flow.

Trusted for over 100 years.

Our Clients