Charge Buckets

Our Charge Bucket Solutions

Whiting’s charge buckets are engineered for performance in the most demanding melt shop environments. Designed for safe, reliable transfer of scrap into electric arc furnaces, each bucket is built to order—optimized for capacity, material type, and crane specifications. Whether you’re upgrading equipment or expanding operations, Whiting delivers proven solutions tailored to your charging process.

Trusted for over 100 years.

Our Clients

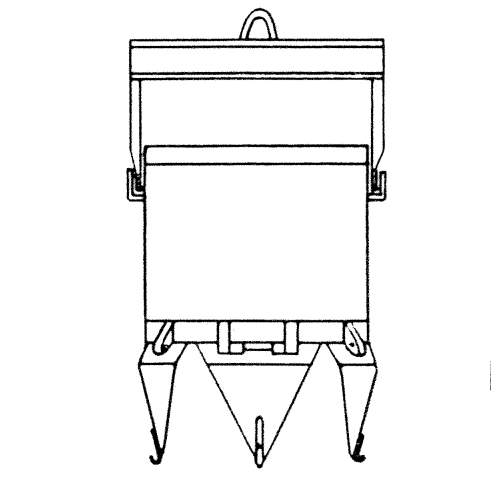

Drop-Bottom Charge Bucket

With a “drop-bottom” charge bucket, the top-charge furnace can be completely charged in a few minutes. The bucket may be loaded while the furnace is in operation, with the charge arranged in the bucket precisely as you desire it placed in the furnace.

Buckets are designed to require minimum headroom and can hold a volume equal to the volume of the furnace to be charged. Thus’ one bucket can completely fill the furnace.

The back charging operation is sometimes used to increase the charge of molten metal above the rated capacity of the furnace, for especially large heats. Or back charging may be resorted to when especially light scrap is used and the initial charge does not produce the tonnage required for the heat. After the original charge has partially melted, there is room in the furnace for a second charge – a back charge.

Read More

Clamshell Type Charge Bucket

The Clamshell type charge bucket is the most common used charge bucket for charging the top charge Electric Arc Furnace. The Whiting Clamshell charge bucket is loaded with scrap steel on the ground.

Once it is loaded the crane operator will hoist the charge bucket up with the main hook and position the charge bucket directly above the top charge electric arc furnace. The Whiting Clamshell charge bucket uses the cranes auxiliary hook to pull on wire rope cables to open the bottom of the charge bucket. The charge is now in the electric arc furnace shell and the clamshells return to their closed position. The clamshells have a flat surface on the bottom to allow the charge bucket to sit safely on the ground when not in use or while the scrap steel is loaded.

Read More

Orange Peel Type Charge Bucket

Different mechanisms are employed to hold and release the orange-peel segments-the oldest, perhaps, being a rope tied around a hook on each segment.

When the heat of the furnace burns through the rope, the segments are released; opening the bucket, and allowing the charge to fall into the furnace. (If the furnace is cold, a torch is applied to the rope through the furnace door.) The ease with which the rope-tie bucket is closed makes it very popular. As the open bucket is lowered into a bottom-closing stand, the dished head receives the segments and closes them as the bucket is lowered. The central section of the dished head is cut out, exposing the rope hooks for convenient tying. The rope is passed once or twice around the six hooks and securely knotted, completing the operation. The Whiting Rope – Tie Bucket is sturdily built to withstand the mechanical shocks of charging and to withstand furnace heat. The design of the segments prevents damage to refractory walls when the charge is released … the rope hooks being well shielded behind the contour of the bottom, preventing the hooks from damaging refractory walls or arches. Whiting Rope – Tie Buckets may be furnished with lifting stirrups, bail, or yoke-depending upon individual requirements. The yoke is recommended where crane clearances are limited.

Read More