Foundry & Steel

High-Performance Melt Shop Equipment for Ferrous and Specialty Steel Producers

Engineered Systems for Steel Casting, Refining, and Finishing

Whiting Equipment Canada supplies integrated melt shop equipment for steel foundries and production facilities that require precision, durability, and safety at scale. From raw material melt to final alloy tuning, our systems are built to support the production of carbon steels, stainless steels, and high-performance alloys.

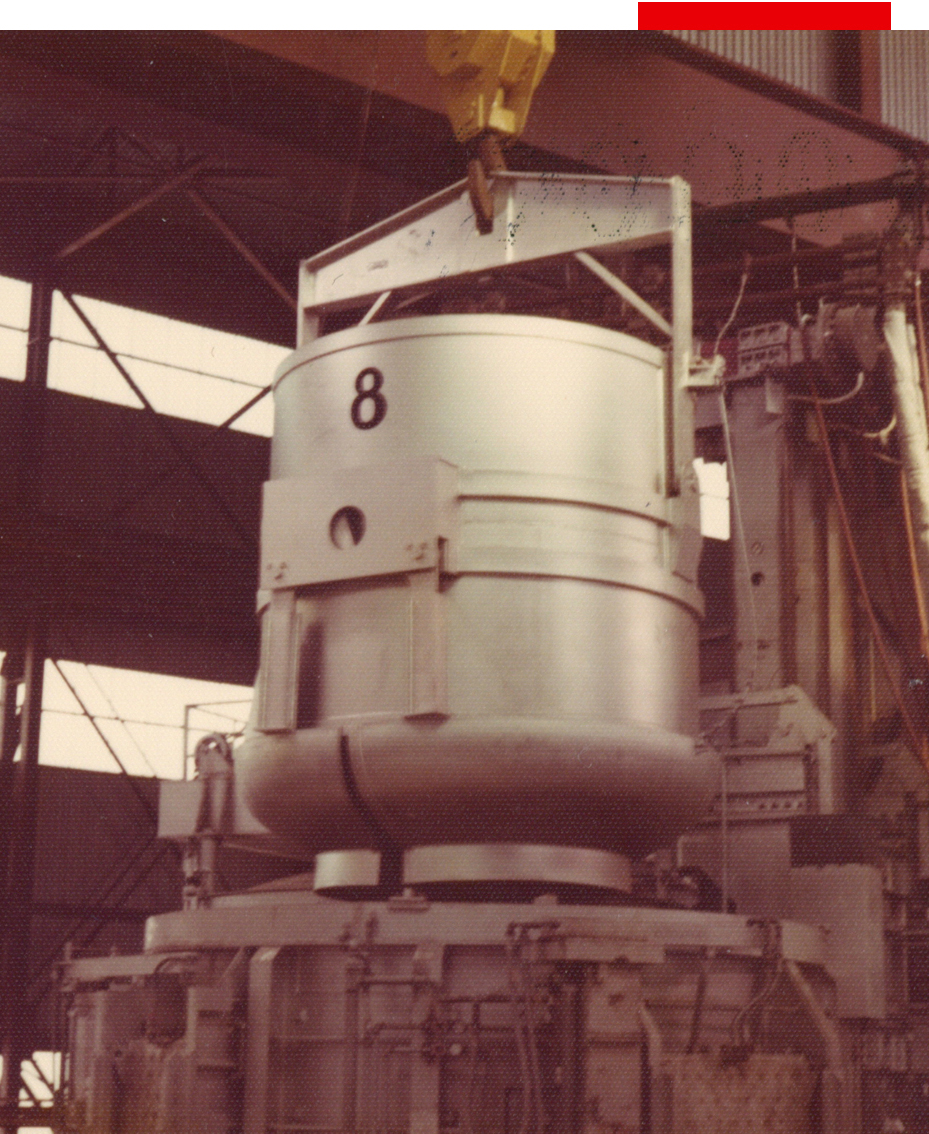

With a legacy dating back to 1914 and a track record that includes designing over 75% of AOD heavy equipment systems in North America, Whiting Equipment is a preferred partner for both greenfield steel plants and melt shop upgrades.

Trusted for over 100 years.

Our Clients

Contact Our Experts

Key Products

- Electric Arc Furnaces (EAFs): Scrap-melting and alloy-tuning furnaces designed for clean steel production.

- Argon Oxygen Decarburizers (AODs - Linde Process): High-efficiency converters for stainless and specialty steels.

- EZ Pour® Ladle Gearing: Motorized/manual tilting with automatic braking for safe, controlled pours.

- Slag & Ladle Transfer Cars: Reduce crane dependency while optimizing material handling on the melt floor.

- Steel Mill Crane Ladles: AISE Specification #9, refractory-lined fabricated vessels used to transport and pour molten metal.

- EAF Charging Buckets: Heavy-duty steel fabrications specifically designed to hold and deliver scrap metal into Electric Arc Furnaces (EAF)

- Upgrades and Modernization: Update to existing equipment, whether Whiting-designed or other manufacturers.

- Furnace Transformers: Supply of Shell and Core Type Transformers.

- Hydraulic Power Units: Supply of Proportional Valve control.

Precision, Safety & Throughput

Whiting designs equipment for continuous uptime, safe operations, and flexible integration with downstream casting. Every solution is engineered with plant efficiency and steel quality in mind.

Upgrading or building a melt shop?

Partner with Whiting Equipment for fully integrated, high-performance steel production systems.