Materials Handling

Engineered Solutions for High-Temperature Mineral Fusion

Whiting Equipment Canada: Keeping Material Handling Moving at the Speed of Your Business

Whiting Equipment Canada’s strategic partnership with Handling Specialty enhances its ability to deliver specialized material handling and industrial automation equipment tailored to meet the increasing demands of various industries, including aerospace, automotive, entertainment, rail transportation, energy, and advanced manufacturing.

In business since 1963, Handling Specialty excels in engineering custom solutions for complex material handling challenges. With advanced manufacturing facilities, Handling Specialty provides comprehensive services that include design, engineering, manufacturing, testing, and installation.

Customized Solutions for Every Need

You need it, we have built It.

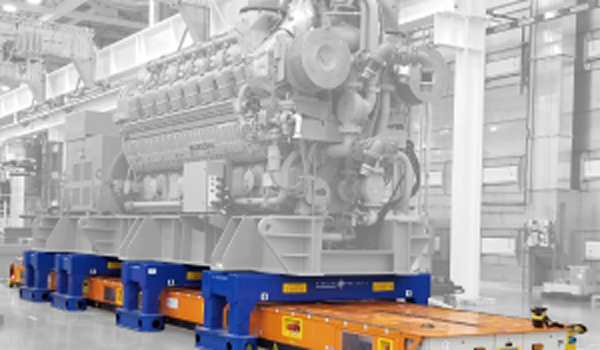

Automated Guided Vehicles (AGVs)

AGVs are autonomous transportation systems designed to efficiently move materials in industrial environments. Guided by sensors, markers, or software, AGVs operate autonomously, eliminating the need for human intervention and enhancing workflow efficiency. They are ideal for repetitive tasks and high-precision logistics, minimizing errors and downtime. With programmable routes and real-time control, AGVs ensure safe and reliable operation in sectors such as manufacturing, warehousing, and distribution, where automation enhances productivity and supports stringent safety and performance standards.

Manually Guided Vehicles (MGVs)

MGVs are reliable transport systems designed for heavy-duty industrial use. Ideal for handling challenging loads like furnace parts and steel coils, MGVs are custom-built to fit specific facility layouts. They enhance workflow efficiency, reduce manual labor, and minimize operational downtime.

With their robust construction and precision movement, MGVs are well-suited for industries requiring high safety and reliability standards, offering a practical, human-operated solution for controlled material transport in complex environments.

Custom Work Positioners

Custom work positioners improve safety and ergonomics in manufacturing and maintenance tasks by lifting, tilting, or rotating heavy components for optimal accessibility. These devices are tailored to meet your unique workspace needs, helping reduce worker strain and increase productivity.

With rugged construction and precise control, our positioners support safe handling of awkward or oversized parts, streamlining operations in industrial, metallurgical, and fabrication settings.

Turntables and Rotators

Turntables and rotators are built for smooth, controlled 360° movement of heavy components during welding, inspection, or assembly. These rugged devices reduce the need for manual repositioning and are available in various sizes and configurations to meet your exact load and spatial requirements.

They are ideal for enhancing productivity and accuracy in manufacturing lines, foundries, and specialty metalworking facilities where precise handling is crucial.

Transfer Cars

Transfer cars safely and efficiently move heavy loads—like molten ladles, steel ingots, or mechanical assemblies—across production lines. Constructed with robust steel and heat-resistant insulation, they can be powered by AC or DC motors and feature customizable controls for automated or semi-automated use.

Designed to reduce operator risk and ensure consistent handling of high-value materials, transfer cars improve workflow reliability and operational safety. Their tailored design supports demanding industrial environments where precision and durability are essential.

Towline Carriers

Towline carriers offer repeatable, controlled transport, ideal for assembly lines and warehouses that require predictable material flow. Operating along a fixed path, they are designed to transport heavy or irregularly shaped loads with precision. When paired with our advanced control systems, towline carriers help boost throughput, minimize human error, and optimize material handling.

Their robust design and precision movement make them an effective solution for improving logistics and efficiency in manufacturing and processing environments.

Below-the-Hook Lifting Devices

Below-the-hook lifting devices are specially engineered to safely and efficiently handle oversized or awkward loads in manufacturing and steel-handling operations. Custom-built for each application, they meet or exceed ASME standards to ensure safety and reliability. Designed for lifting items like rolls, coils, ladles, and molds, these devices deliver secure, repeatable performance while protecting structural integrity.

They help streamline operations, enhance operator safety, and ensure consistent handling across your facility, making them essential tools in demanding industrial environments.

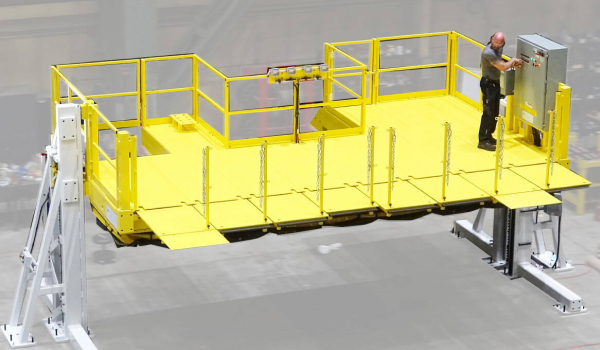

Personnel Lifts

Designed to safely elevate workers to various heights for maintenance, installation, or construction tasks. Commonly used in manufacturing, warehouses, and construction, these specialized lifts provide a stable platform for accessing elevated work areas. Their design varies based on application, including scissor lifts, boom lifts, and vertical mast lifts.

Personnel lifts increase worker safety by reducing the need for ladders or scaffolding and are equipped with guardrails, attachment points for harnesses, and emergency controls.

Tilters & Up-enders

Tilters and up-enders simplify the safe, efficient rotation of large or awkward items. Whether repositioning product from horizontal to vertical or positioning complex assemblies, they eliminate manual strain and reduce risk. Built to your specifications, each unit features a heavy-duty frame and precise motion control for reliable performance.

Ideal for the automotive, foundry, and fabrication industries, these solutions support orientation changes required for assembly, inspection, or maintenance, thereby improving workflow and ensuring the safe, repeatable handling of challenging loads.

Stage Lifts

Stage lifts offer controlled vertical movement of heavy loads across multiple levels in manufacturing and material handling settings. Engineered for high-duty cycles, they handle large components with accurate, repeatable positioning. Integrated safety locks and automation options improve operational safety and efficiency, making them ideal for environments where vertical space is maximized.

These lifts enhance accessibility, reduce manual handling, and facilitate the seamless transport of bulky items between floors or platforms, thereby boosting throughput in demanding industrial applications.

In-floor Lifts

In-floor lifts deliver powerful lifting capabilities while preserving valuable floor space. Installed flush with the facility floor, they provide an unobstructed, seamless workspace when not in use. Ideal for production lines, maintenance bays, and ergonomic workstations, these lifts safely manage large, heavy components with ease.

Their discreet, space-saving design enhances workflow efficiency without sacrificing strength or durability, making them a practical solution for environments that require reliable lifting performance alongside maximum floor utilization.

Multi-Post Lifts

Multi-post lifts offer powerful, synchronized lifting for large platforms or equipment that require multiple support points. Designed for service bays, manufacturing lines, or heavy equipment assembly, they ensure precise control and balanced load distribution. Available with hydraulic or screw-jack drives, customizable configurations, and built-in safety interlocks, these lifts deliver reliable performance for high-capacity tasks.

Their robust design supports stability and efficiency, making multi-post lifts an ideal solution for demanding industrial lifting applications that require strength, precision, and flexibility.

Electric Jacks

Electric jacks deliver precise, reliable lifting in demanding industrial environments. Designed for quiet operation with minimal manual effort, they are ideal for both stationary and mobile applications. Commonly used to lift transfer cars, rail equipment, and heavy structures during maintenance or assembly, electric jacks offer high weight capacities and integrated safety features.

These systems reduce labor strain, improve maintenance efficiency, and enhance overall safety and security. Their versatility and performance make them essential tools for consistent, high-capacity lifting operations.

Trusted for over 100 years.