Melt Shop Solutions

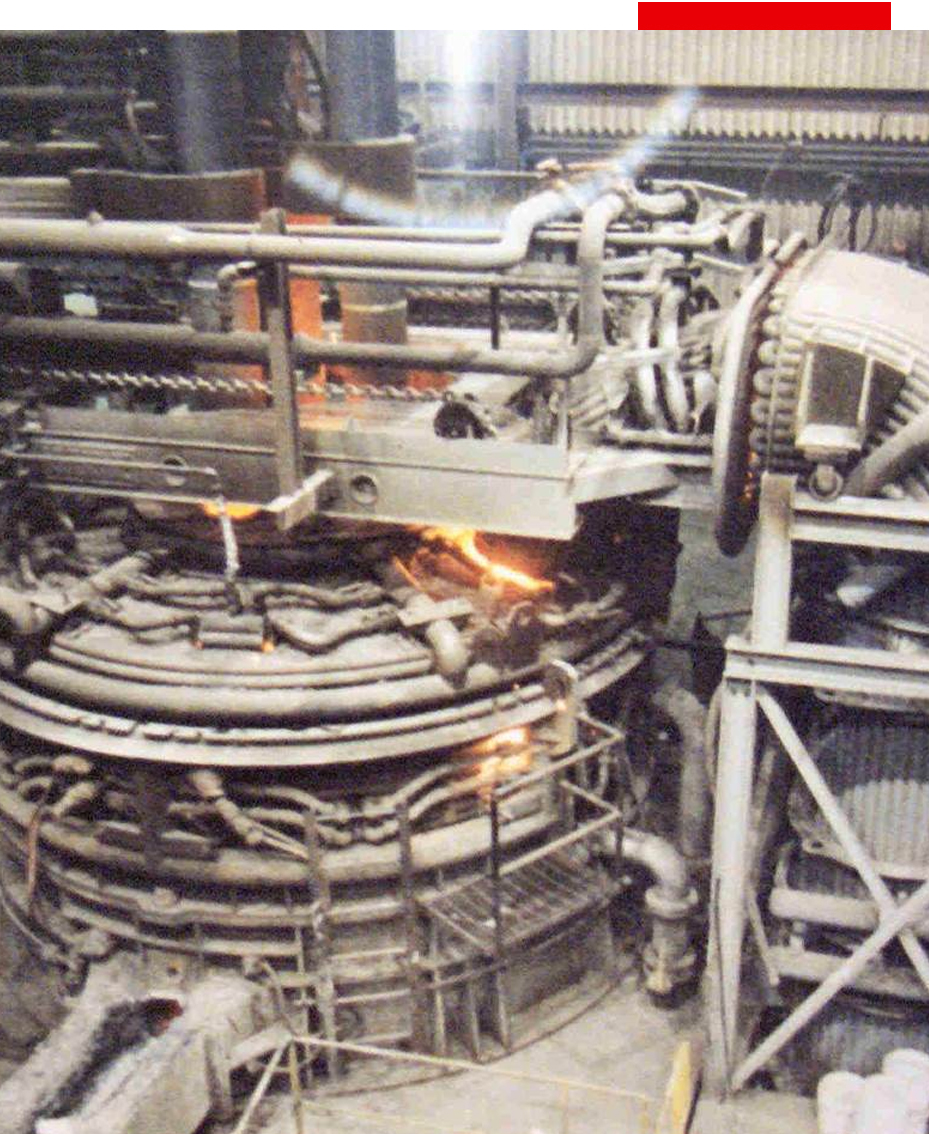

Custom Melt Shop Systems for Specialized Manufacturing Applications

Advanced Furnace Technologies for Alloy, Tool Steel & Precision Metal Processing

Manufacturers working with critical alloys, tool steels, and specialty castings rely on Whiting Equipment’s melt shop systems for tight metallurgy, system reliability, and custom-configured production lines.

Whiting is a vertically integrated manufacturer with control over fabrication, engineering, and field commissioning. We support clients from design through to performance validation, backed by over 100 years of experience in the melt shop and heavy manufacturing environment.

Serving Unique Needs in:

Aerospace & Defense I Advanced Tooling I Specialty Foundries

High-Value Alloy Casting I Forge Shops

Trusted for over 100 years.

Our Clients

Contact Our Experts

Key Products

- Custom Electric Arc Furnaces: Designed for unique chemistries and variable batch sizes.

- Hydro-Arc® Furnaces: Water-cooled, energy-efficient systems offering high throughput and longer refractory life.

- Ladle Relining Platforms & Personnel Lifts: Ergonomic solutions that improve safety, reduce turnaround, and increase reline accuracy.

- Instrumentation & Controls: PLC-5/SCADA-compatible, touch-screen HMIs and automated control integration.

Designed for Precision Manufacturing

Whiting supports operations with specialty metallurgical needs, providing scalable systems built to exacting specifications. Whether you’re producing for aerospace, defense, or advanced manufacturing, our equipment is purpose-built for critical operations.

Need custom equipment for critical manufacturing

processes?

Let’s design a solution built for your process, chemistry, and production goals.