The global energy transition has created an unprecedented demand for lithium. Electric vehicles (EVs), renewable energy storage, and consumer electronics all depend on lithium-ion batteries, making lithium the “white gold” of the 21st century. But while demand is apparent, the methods of lithium extraction are diverse, complex, and often contested.

In 2025 and beyond, three primary pathways dominate the discussion: evaporation ponds, direct lithium extraction (DLE), and hard-rock mining (using spodumene). Each has different strengths, weaknesses, and implications for environmental, social, and governance (ESG) performance. Choosing the right path is not only a matter of economics but also of sustainability, community acceptance, and long-term resource security.

This article breaks down the primary sources of lithium, examines the competing extraction methods, and compares their impacts on water, energy, and refining.

Lithium Sources: Brine, Hard-Rock, Clay

Lithium is not found in pure metallic form. Instead, it occurs as salts dissolved in brines, minerals in hard rocks, or bound within clay deposits.

- Brines: Brine resources are underground reservoirs of saline water that contain dissolved lithium salts, often found in arid regions like the “Lithium Triangle” of Bolivia, Chile, and Argentina. Brines are appealing because the lithium is already in solution, but they vary widely in chemistry, with high levels of magnesium or other contaminants that complicate refining.

- Hard-Rock Minerals: Spodumene, a lithium-rich pyroxene mineral, is the primary hard-rock source. Mined in countries such as Australia, spodumene deposits are crushed, concentrated, and then processed through thermal and chemical steps to produce lithium hydroxide or carbonate. Hard-rock operations are capital-intensive but offer predictable output.

- Clays: Lithium-bearing clays, such as hectorite, represent a growing frontier in the field of lithium extraction. While technically viable, clay projects are still in early stages of commercialization. The chemistry of these deposits often requires unique leaching and refining solutions.

Each resource dictates which extraction technologies are feasible. Brines can utilize evaporation ponds or DLE (Direct Lithium Extraction), an umbrella term for a group of technologies that extract lithium directly from brine without relying on lengthy evaporation pond cycles.

Hard rock requires mining and beneficiation (refers to the treatment of raw ore to improve its economic value by removing impurities or increasing the concentration of the desired mineral). Clays demand custom leaching (a hydrometallurgical process where valuable metals or minerals are dissolved out of solid material using a liquid — usually an acid, base, or other chemical solution).

Evaporation Ponds: Time, Yield, Footprint

Evaporation ponds are the most established method of lithium extraction from brines.

- How it works: Brine is pumped into vast ponds, where solar radiation and wind drive evaporation. As water evaporates, salts precipitate sequentially, concentrating lithium until it can be harvested and refined for use.

- Timeframe: The process is lengthy, typically 12–18 months, depending on climate and brine chemistry.

- Yields: Recovery rates hover between 30–50%, with substantial lithium left behind due to inefficiencies and impurities.

- Footprint: Land use is extensive, with some operations covering dozens of square kilometers.

Advantages

- Low operating costs (uses free solar energy).

- Mature, proven technology.

- Scalable to huge capacities.

Disadvantages

- Long processing times delay revenue.

- Heavy water consumption is often controversial in arid regions.

- Weather-dependent, vulnerable to rainfall and climate variability.

- Relatively low recovery compared to newer technologies.

In regions like Chile’s Atacama Desert, evaporation ponds dominate production, but social and environmental pressures are intensifying. Communities and regulators are increasingly asking whether water-intensive pond systems are compatible with long-term sustainability.

Direct Lithium Extraction (DLE) Methods

DLE has emerged as the most disruptive innovation in lithium extraction. Unlike evaporation ponds, DLE technologies recover lithium in hours or days, rather than years, and can achieve significantly higher recovery rates.

Adsorption

Adsorption uses materials that selectively bind lithium ions from brine. Once loaded, the sorbent is regenerated, releasing lithium into a recovery solution.

- Pros: High selectivity, strong potential for high-purity lithium.

- Cons: Sorbents degrade over cycles; sensitive to impurities.

Ion Exchange (IX)

Ion exchange resins exchange lithium ions for other cations in solution.

- Pros: Continuous operation, adaptable to variable brines.

- Cons: Requires chemicals for regeneration; resin lifespan can be limiting.

Solvent Extraction (SX)

Organic solvents preferentially dissolve lithium salts.

- Pros: High recovery potential.

- Cons: Solvent handling and losses pose environmental risks.

Membranes

Specialized membranes use pressure or electrical potential to separate lithium ions.

- Pros: Modular, compact systems.

- Cons: Susceptible to fouling and scaling; energy intensive.

Advantages of DLE overall:

- Recovery rates of 70–90%, significantly higher than ponds.

- Much faster cycle times.

- Smaller land footprint, less visible environmental impact.

Challenges of DLE:

- Still scaling up to commercial deployment.

- High capex and opex compared to ponds.

- Each brine chemistry requires custom solutions.

DLE may not fully replace evaporation ponds yet, but it is becoming a vital tool in regions where water, land, or time constraints make ponds unsustainable.

Hard-Rock (Spodumene) Routes

Hard-rock mining remains the second-largest source of lithium globally.

- Mining and processing: Spodumene ore is mined, crushed, and concentrated by flotation. The concentrate is then calcined at high temperatures, making lithium more accessible, and processed chemically to yield lithium compounds.

- Recovery and speed: Recovery rates can exceed 70–80%, with continuous throughput that avoids the long delays of evaporation ponds.

- Footprint: Requires less land area than ponds but involves significant tailings and waste rock.

- Energy demand: High, particularly in calcination and chemical processing.

Pros

- Reliable supply in stable jurisdictions like Australia.

- Predictable output and shorter project timelines.

- Higher recovery efficiency than ponds.

Cons

- High carbon footprint without renewable energy.

- Significant chemical and energy requirements.

- Waste management challenges.

Hard rock is particularly important for Western supply chains seeking stable and secure lithium sources outside of South America.

Water, Energy & ESG (Environmental, Social, Governance)

ESG considerations are increasingly shaping the viability of lithium projects. Investors, automakers, and regulators all demand proof that extraction methods are sustainable.

- Water use:

- Ponds: High water withdrawal from fragile ecosystems.

- DLE: Uses less water but requires chemical reagents.

- Hard-rock: Lower water footprint than ponds, but water is still needed in processing.

- Energy use:

- Ponds: Low energy footprint due to solar evaporation.

- DLE: Higher energy demand for pumps, membranes, and regenerants.

- Hard-rock: Very high energy for mining, calcination, and processing.

- Social license:

Communities increasingly push back against ponds due to water concerns. DLE and hard-rock may gain more acceptance if paired with renewable energy and strong waste management practices.

Environmental/Water Comparisons

- Evaporation ponds deplete groundwater in already arid regions.

- DLE can recycle water, but it depends on chemical sustainability.

- Hard-rock avoids direct water conflicts but creates emissions concerns.

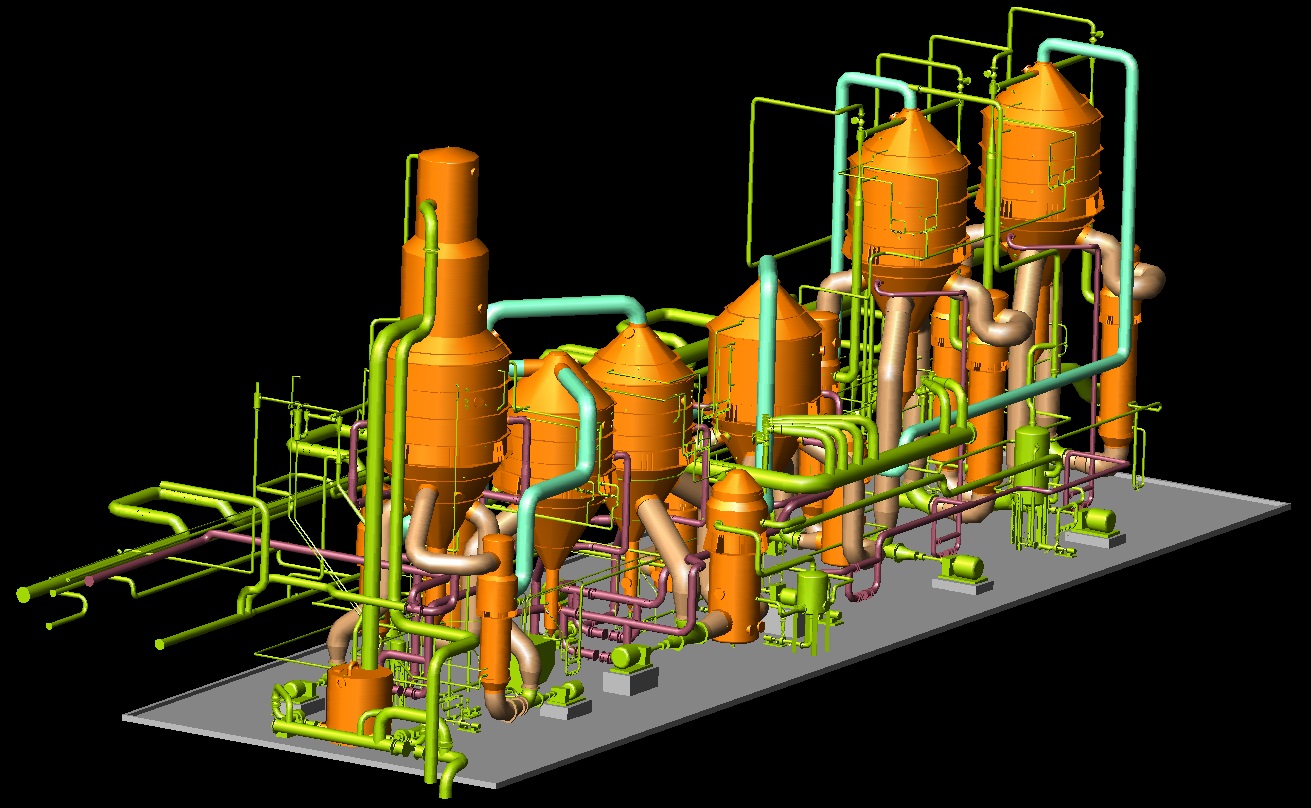

From Extraction to Refining (Overview)

Extraction is only the beginning. To become battery-grade, lithium must undergo a refining process.

- Pre-treatment – Impurities like magnesium and calcium must be removed. Brines with high impurity loads require extensive pre-treatment. Failure to remove contaminants early can damage equipment, foul membranes, or reduce the efficiency of the crystallizer. Refining systems must be explicitly designed for the chemistry of the source.

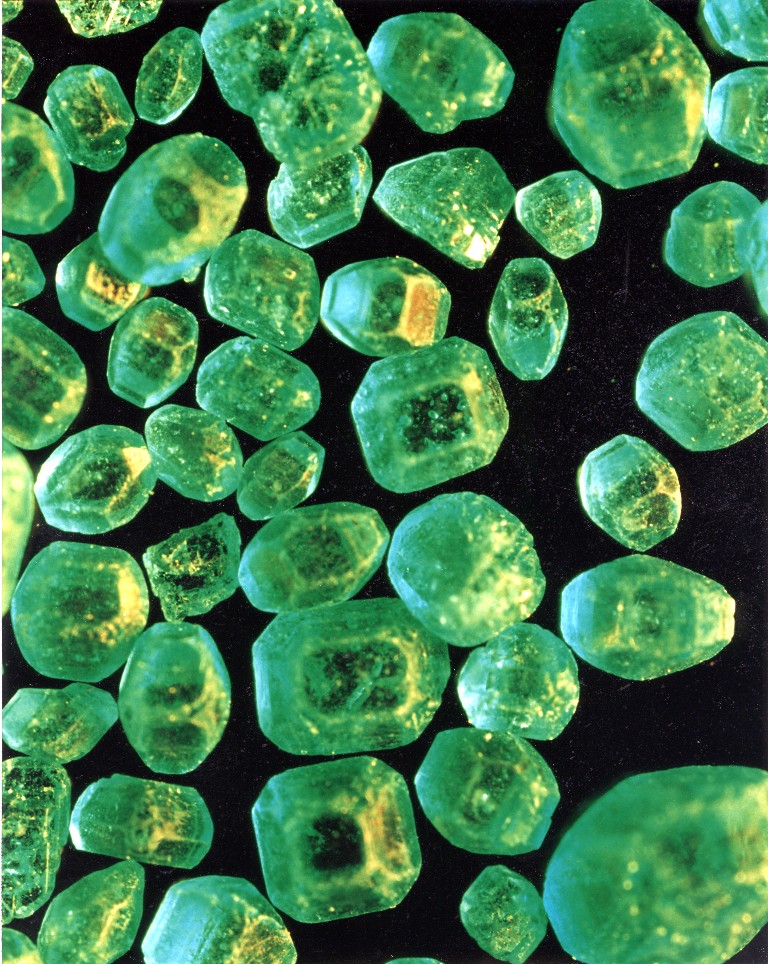

- Crystallization – A core technology that controls how lithium crystals form and grow, producing compounds of consistent purity.

- The resultant refined compounds – Battery-grade products include lithium hydroxide monohydrate, lithium carbonate, lithium chloride, and lithium sulfate.

Conclusion

The future of lithium supply hinges on a delicate balance between speed, cost, recovery, and sustainability.

- Evaporation ponds remain dominant but face growing criticism over water use and long lead times.

- Direct Lithium Extraction offers speed, efficiency, and high recovery but requires further commercialization and energy optimization.

- Hard-rock mining provides a reliable supply at scale, but its carbon intensity raises concerns without renewable power integration.

No single method is universally best. The right choice depends on resource type, regional constraints, ESG expectations, and end-market requirements. What is certain is that refining technologies such as evaporation and crystallization remain central to transforming raw lithium into the high-purity products that power modern life.

Why Choose Whiting?

The Whiting team, through its licensee Swenson Technology, has decades of expertise designing evaporation and crystallization systems tailored to brines, hard-rock, and clay sources. From pilot testing to commercial-scale plants, our engineered solutions are built to maximize lithium recovery, reduce costs, and deliver battery-grade purity.

Contact us to discover how we can assist you in designing the optimal path forward to achieve your extraction and refining objectives.

Frequently Asked Questions

What role does Whiting and Swenson Technology play in lithium production?

Whiting Equipment Canada, through Swenson Technology, designs and supplies the evaporation and crystallization systems central to refining high-purity lithium.

What are the benefits of advanced crystallization technology?

They enable producers to maximize lithium recovery, enhance purity, and lower costs.

Which lithium compounds can be refined?

Common products include lithium hydroxide, lithium carbonate, lithium chloride, and lithium sulfate.

How are refining processes developed?

Projects move through modeling, bench testing, pilot testing, and full-scale design to ensure reliable performance.