Refining Routes (Li₂CO₃ vs LiOH)

The global surge in electric vehicle (EV) demand has placed enormous pressure on lithium supply chains. At the heart of these supply chains are two dominant refining routes: lithium carbonate (Li₂CO₃) and lithium hydroxide (LiOH). Each compound serves distinct applications in the battery industry, and refining processes must be tailored accordingly.

Whiting Equipment Canada Inc., working through its licensee Swenson Technology, has decades of experience engineering crystallization trains for both carbonate and hydroxide products. Swenson’s track record dates back to the 1950s, covering Li₂CO₃, LiOH·H₂O, LiCl, and Li₂SO₄. This depth of expertise underscores the ability to refine a broad spectrum of lithium compounds to battery-grade purity.

- Lithium Carbonate (Li₂CO₃) is widely used in cathode chemistries such as lithium cobalt oxide (LCO) and lithium iron phosphate (LFP). Its production requires careful management of impurities, as contaminants such as magnesium and calcium can disrupt downstream performance.

- Lithium Hydroxide (LiOH) has become the preferred feedstock for high-nickel cathodes (e.g., NCM and NCA), prized for higher energy density. Producing LiOH requires advanced control of crystallization to meet demanding purity and particle size specifications.

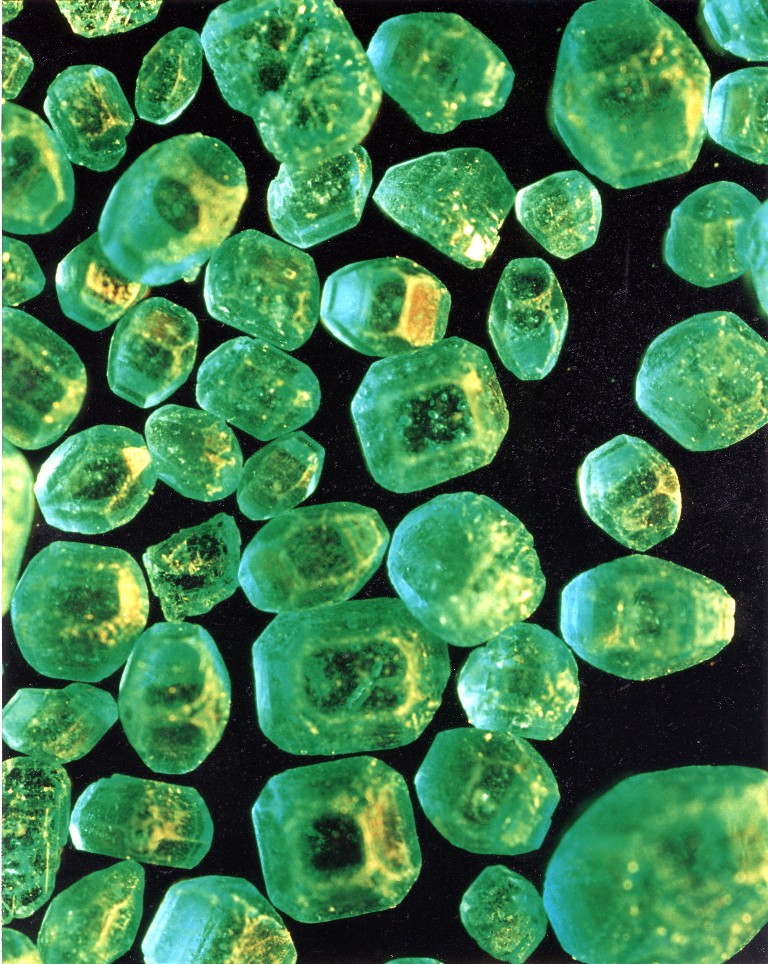

Both routes ultimately depend on crystallization as the core refining step. Whether producing carbonates or hydroxides, controlling crystal growth, morphology, and separation defines the quality of the final product.

Purification & Impurity Removal

At its core, lithium refining is about removing contaminants and isolating pure lithium salts. Brines, hard-rock concentrates, or recycled materials all bring unique impurity profiles that must be addressed through engineered process design.

Crystallizers play a central role here:

- Impurity Rejection – Properly designed crystallization systems ensure unwanted salts remain in the mother liquor rather than embedding in lithium crystals.

- Process Modeling – Every train design begins with detailed thermodynamic and chemical modeling to anticipate impurity behavior under different conditions. This modeling forms the basis for effective strategies for contaminant removal.

- Bench & Pilot Testing – Small-scale glassware testing and pilot crystallizers generate yield, purity, and morphology data. This information informs the design of commercial trains capable of reliably achieving battery-grade purity.

Whiting and Swenson’s approach emphasizes tailoring the crystallizer design to the source material—whether high-chloride brines, spodumene-derived solutions, or blends—ensuring impurities are effectively separated at each stage.

Crystallization Train Design

A crystallization train is a sequence of crystallizers and supporting equipment arranged to achieve high recovery and purity. Each train is designed to maximize throughput while ensuring consistent product quality.

Core Design Elements:

- Crystallizer Types – Swenson pilot facilities employ draft tube baffle (DTB), forced circulation (FC), evaporative, and cooling crystallizers. Each type contributes differently to nucleation, crystal growth, and fines management.

- Staged Operation – Multiple crystallizers in sequence allow progressive concentration, growth, and separation, improving both yield and control.

- Customization – Every train is tailored to customer operating conditions, brine chemistry, and final product specifications.

Train Sizing & Debottlenecking

Train design is not static. Over time, demand growth or process bottlenecks may require re-evaluation. Swenson’s structured methodology—modeling, bench testing, pilot data, and eventual commercial sizing—provides the foundation for scaling up while avoiding common pitfalls. Debottlenecking often involves adjusting crystal classification, circulation rates, or centrifuge performance to improve throughput without sacrificing quality.

Evaporation & Heat Integration

Lithium refining trains depend heavily on evaporation, both to concentrate feed streams and to control supersaturation. Efficient use of thermal energy can make the difference between a viable project and one burdened by high operating costs.

- Evaporator Types – Forced circulation and falling-film evaporators are employed in pilot testing and commercial plants. FC designs handle scaling brines effectively, while falling-film units provide efficient heat transfer at low residence times.

- Heat Integration – Early-stage modeling identifies opportunities to balance utilities and recycle heat within the process. Multi-effect arrangements and optimized exchanger networks reduce steam demand and operating costs.

- Process Efficiency – The overriding goal is to reduce costs and increase revenue by improving energy efficiency, aligning with ESG pressures for sustainable refining.

Energy & Utilities Balance

Every lithium refining project must strike a balance between steam, electricity, cooling water, and other utility demands. Modeling and simulation are critical here, ensuring energy efficiency is built into the design before significant capital is committed.

Quality (Battery-Grade) & Analytics

Battery-grade lithium requires not just high chemical purity but also consistent particle size, morphology, and moisture content. Meeting these specifications requires rigorous process control and robust analytics.

- Bench Testing Analytics – Glassware testing provides early data on yield, purity, and morphology.

- Pilot QA Data – Pilot testing reveals fouling tendencies, washing requirements, and centrifuge performance.

- Inline Analytics & QA – Increasingly, inline sensors are deployed to monitor purity, particle size distribution, and concentration in real time. This integration reduces variability and supports continuous quality assurance.

By embedding analytics and QA throughout the crystallization train, Whiting and Swenson ensure that battery-grade standards are consistently achieved, not just in test batches but in full-scale continuous production.

Waste / By-Product Handling (Na₂SO₄)

Lithium refining often generates sodium sulfate (Na₂SO₄) as a by-product, especially when treating brines with high sulfate content. Effective management of this stream is crucial for both compliance and potential by-product valorization.

- Experience with By-Products – Swenson has documented experience handling Na₂SO₄ and Na₂SO₄·10H₂O (sodium sulfate decahydrate).

- Waste Minimization – Proper crystallizer design ensures sodium sulfate is separated cleanly, preventing contamination of lithium products.

- Potential Valorization – In some cases, sodium sulfate can be marketed for industrial use, turning a disposal liability into a revenue stream.

Case Architectures

The pathway from concept to commercial plant follows a structured, staged approach:

- Modeling & Simulation – Predicting thermodynamic behavior, impurity solubility, and energy demand.

- Bench Testing – Proof of concept and early crystal data collection.

- Pilot Testing – Evaluation of fouling tendencies, centrifuge performance, and product morphology under realistic conditions.

- Commercial Implementation – Equipment sizing, cost estimation, fabrication, delivery, and commissioning.

This disciplined workflow underpins successful case architectures, ensuring each system is designed for optimal performance under specific operating conditions.

Conclusion

Designing lithium carbonate and lithium hydroxide crystallization trains for battery-grade applications requires a comprehensive approach that encompasses refining route selection, impurity removal strategies, staged crystallizer design, evaporation integration, and rigorous QA. Whiting Equipment Canada and Swenson Technology bring unmatched expertise to this challenge, drawing on decades of experience in crystallization and evaporation, backed by pilot testing facilities and global manufacturing capacity.

Our systems are engineered not only to deliver high-purity lithium products but also to optimize long-term efficiency, sustainability, and adaptability. From sodium sulfate management to inline analytics, each aspect of the train is designed with commercial viability and ESG compliance in mind.

If your project requires a lithium refining solution that balances purity, efficiency, and reliability, the Whiting team can help. With Swenson’s proven crystallization technologies and Whiting’s engineering and manufacturing expertise, you’ll have a partner capable of designing, fabricating, and commissioning a complete refining train—built to perform, designed to last, and tailored to your unique feed source and product requirements. Contact us to discuss your project requirements.