How to Specify a Ladle Transfer Car

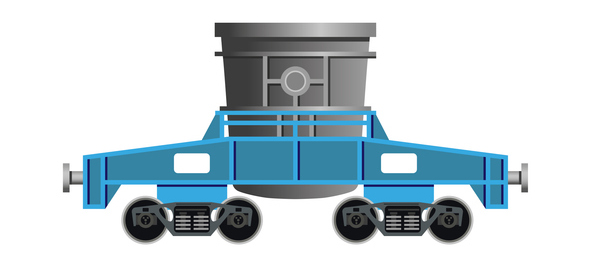

In a melt shop, the ladle transfer car is not just another piece of equipment—it is a critical link between furnace, preheat station, and caster. Any failure or under-specification can cause production delays, safety risks, and costly downtime. That’s why it is essential to approach ladle transfer car specification with rigor, ensuring that every design choice aligns with duty cycles, safety requirements, and long-term reliability.

This article outlines the key specification areas buyers and engineers should evaluate when drafting a request for quotes (RFQs) or assessing vendor proposals.

Load Cases & Capacity

The first step in specifying a ladle transfer car is to define the load capacity.

- Single-load rating: Cars must safely carry the maximum ladle weight, often between 80 and 300 tons, depending on the melt-shop scale.

- Dynamic loading: Design must account not only for static weight but also for forces during acceleration, deceleration, and emergency stops.

- Future capacity: Plants planning furnace upgrades should over-specify car capacity to accommodate larger ladles, preventing obsolescence.

Vendors should provide finite element analysis (FEA) of car frames to demonstrate structural resilience under repeated loading cycles.

Tracks, Wheels & Drives

Reliability depends heavily on the undercarriage.

- Tracks: Proper rail sizing and alignment prevent derailments and uneven wheel wear. For high-duty cycles, hardened rails extend life.

- Wheels: Forged steel wheels with heat-resistant coatings can withstand the extreme environment near molten steel. Wheel diameter and flange geometry should be sized for both load and rail conditions.

- Drives: Variable-frequency drives (VFDs) allow smooth acceleration and deceleration, reducing stress on mechanical systems and enhancing stopping control.

An underspecified drive system can cause jerky starts or poor positioning accuracy, both of which undermine takt time compliance. Whiting Equipment Canada’s sales and engineering personnel address these concerns with decades of experience behind them.

Brakes & Stopping Distance

Safe stopping is non-negotiable when transporting molten steel.

- Redundant systems: Modern cars typically include dynamic electric brakes, mechanical disc brakes, and an emergency braking system (often magnetic rail brakes).

- Stopping distance: Specifications must define the maximum allowable stopping distance at full load and speed. Vendors should calculate this under worst-case scenarios.

- Controlled deceleration: VFDs combined with braking resistors or regenerative braking ensure cars stop smoothly, protecting ladles and rails.

Safety PLC & Interlocks

A ladle transfer car specification must include advanced safety logic.

- Safety PLCs: Independent, fail-safe control systems prevent movement if unsafe conditions are detected.

- Interlocks: Cars integrate with shop automation to ensure they only move when transfer paths are clear. Examples include rail alignment sensors, gate switches, and obstacle detection systems.

- Emergency stops: Strategically placed e-stop buttons enable operators to immediately shut down the system in the event of a hazard.

Integrating safety logic with plant-wide automation creates a safer environment and prevents costly accidents in your melt shop.

Weighing & Load Cells

Accurate weight measurement is increasingly standard in ladle transfer car design.

- Integrated load cells provide real-time ladle weight, supporting precise alloy additions and tap-to-tap tracking.

- Accuracy requirements: ±0.5% accuracy is common, but higher precision may be specified for specialty grades.

- Data integration: Weight data should feed directly into Level 2 automation or MES platforms for process control and traceability.

Without weighing capability, operators rely on estimates that can lead to inconsistent alloying and higher material costs.

Thermal Protection

The environment for transfer cars is extreme. Cars frequently operate near furnaces, slag pits, or ladle preheat stations, exposing electrical and mechanical systems to high radiant heat.

- Heat shielding: Electrical boxes, cables, and sensors should be protected with refractory-lined housings or thermal blankets.

- Cooling options: Some designs employ forced-air or water-cooled housings for sensitive electronics.

- Component rating: Vendors should specify maximum sustained operating temperatures for motors and sensors.

Thermal protection ensures reliable operation and prevents premature failures in high-heat zones.

Acceptance Testing

Even the best specification is incomplete without robust acceptance testing.

- Factory Acceptance Test (FAT): Conducted at the vendor site to verify design compliance, load simulation, and control logic.

- Site Acceptance Test (SAT): Performed at the melt shop under real operating conditions, confirming integration with rails, automation, and safety systems.

- Performance benchmarks: Tests should measure travel speed, stopping distance, load cell accuracy, and safety interlock functionality.

Requiring both FAT and SAT in the RFQ process ensures that buyers receive equipment that meets safety and performance commitments before production begins.

Conclusion

Specifying a ladle transfer car is not a box-ticking exercise—it is a critical step in safeguarding throughput, safety, and long-term ROI in the melt shop. Proper attention to load cases, track and drive design, braking, safety PLCs, weighing systems, and thermal protection helps ensure that cars perform reliably across thousands of cycles.

Whiting has decades of experience engineering transfer cars for North American melt shops. Our designs emphasize duty-cycle resilience, advanced safety systems, and full integration with automation platforms. Whether you are drafting an RFQ for a new build or modernizing existing equipment, Whiting can provide the specification expertise and engineering support to ensure the success of your project.

Pro Tip: Find a company that has built Transfer cars for the metallurgical industry, with years of experience, to ensure your project is built with expertise.

Contact our team to discuss your ladle transfer car requirements and develop your next RFQ backed by proven expertise.